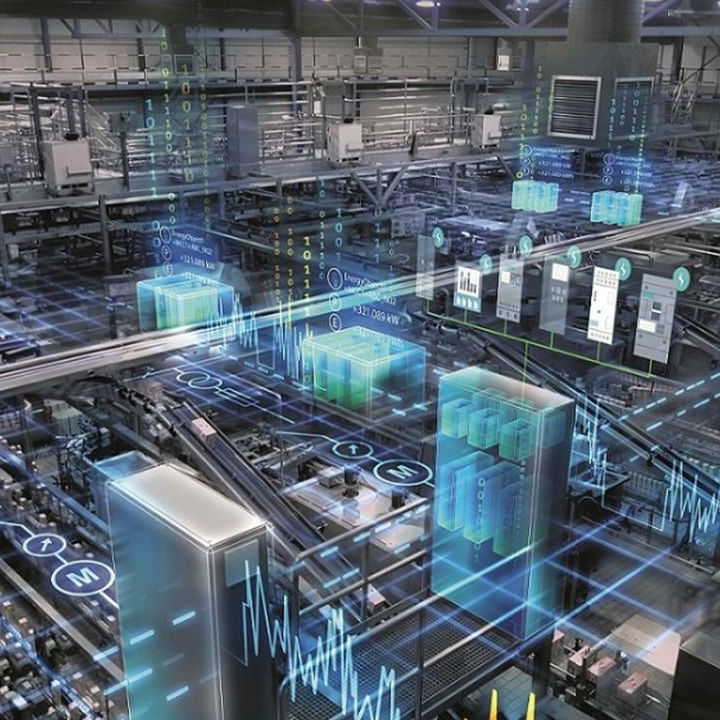

Digital solutions

Digital production simulation systems

We use simulation to deeply understand the operation and conditions of production lines, production cells and intralogistics systems. This help us not only in the design, but back in the visioning phase to get a more precise picture on the future operation. The designed conceptional machine parts have realistic physical and behavioral features, enabling us to reach more than 90% precision in modeling. Our digital design and validation toolset is supplemented by solutions employing VR (virtual reality) and AR (augmented reality) technologies. These extremely innovative solutions of the I4.0 initiative allow for creating the computer models of production equipments in the highest details possible, practically making them able to produce and transport products virtually.

Production and material flow simulations

Developing digital twins

Virtual deployment

Developing AR/VR solutions

Flexible production lines

Our company focuses on solutions creating online connections between physical equipments and their virtual digital twins. The two running in parallel ensures production experts can get much more insights than what is possible today about the production machinery, and to first perform optimization measures on the digital twins.

New developments will enable production systems to flexibly adapt to the manufactured products. Employing machine learning may also become a reality for such systems.

IIoT solutions, intelligent measuring systems

It’s an old practice to collect data from manufacturing equipments and production lines, just as displaying and archiving such data is. Consequences from data, however, have been concluded by humans with especially complex knowledge and a deep understanding of the processes. New technologies are aimed at developing intelligence for systems to automatically conclude information and consequences relevant for production from the ever-growing data sets instead of personal efforts. In addition, speed is another top priority, since real-time analysis may allow for immediate feedbacks to the production processes. Cloud solutions enable for aggregating and evaluating data of many or all production systems (even those operating on different sites), and to use the results to optimize productivity.

Development and demonstration infrastructure

You can view and analyze our digital solutions in our demo system that we continuously expand. The factory model built in our office uses and showcases a digital (virtual) model of a complete production line, that has been partially implemented in physical form as well. The infrastructure is capable of demonstrating I4.0 developments, helps to understand the concept of digital twins, and uses specific examples to understand the process of virtual deployment.