Goals

- Troubleshooting failures and unexpected shutdowns

- Upgrading the drive and control system, ensuring long-term operability

- Full synchronisation of machine units to increase productivity

- Simplify operator work and unify the interface with other lines

- Compliance with safety and standards requirements

Challenges

- Obsolete servo drives, difficult or impossible to repair

- High control complexity (3 PLC and mixed communication protocols)

- Interface and control system did not support modern software and remote management

Solution

- Complete PLC and peripheral replacement with Allen-Bradley safe-PLC integration

- Installation of high performance Allen-Bradley servo drive system and synchronous servo motors

- Precise synchronisation of machine units for continuous and coordinated operation

- Ergonomic, graphical HMI design with unified user logic

- Installation of magnetic transmitters and proportional valves for more stable control

- New safety enclosure and full CE compliance

- Communication simplification on Ethernet/IP basis (CIP-motion, CIP-sync, CIP-safe)

Results

- Productivity increase: +50% thanks to the coordinated operation of the machine units

- Reduction in reject rate: 20–30% fewer rejects due to faster ramp-up

- Reduction in downtime: savings of €50,000-80,000 per year

- Maintenance cost reduction: annual savings of €20,000-30,000

- Investment cost savings: >50% additional production compared to a new production line at a price of 20-25%.

- Lifetime extension: +10-15 years of fail-safe operation

Project menus

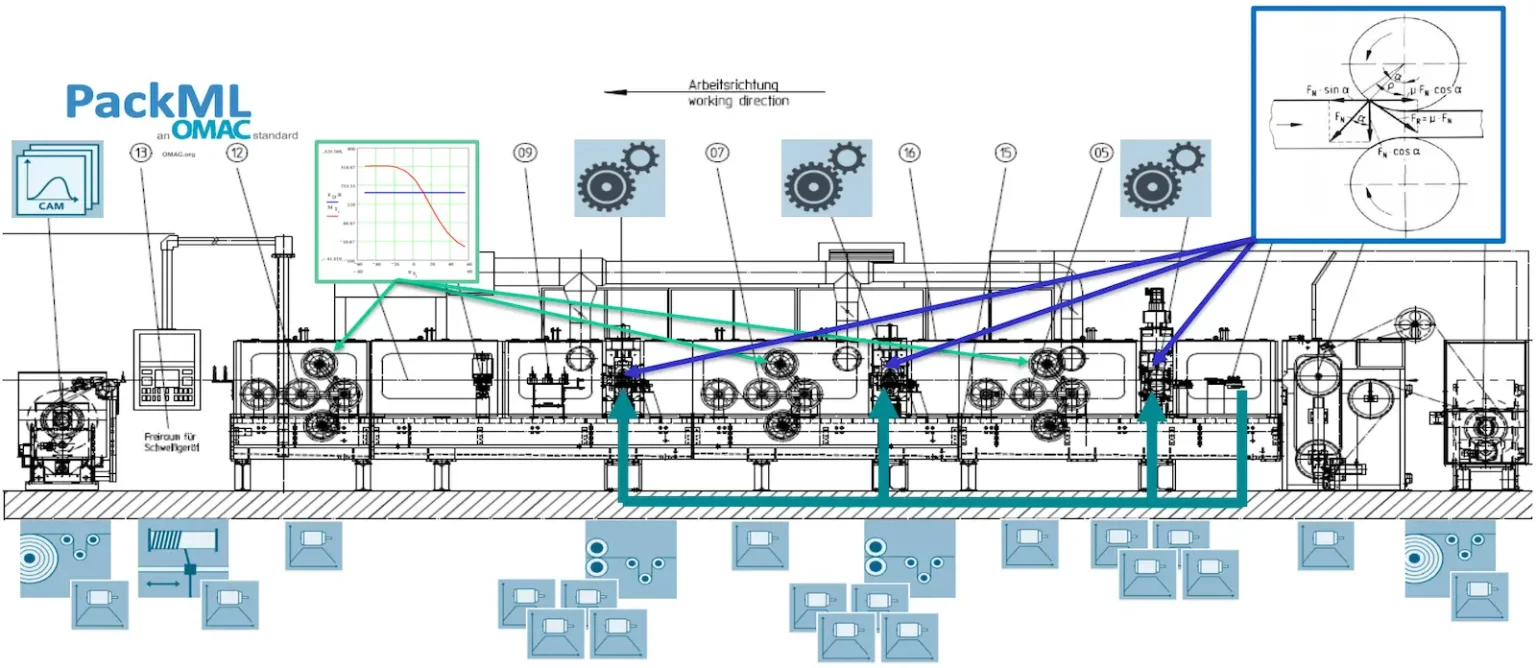

Our partner based in Eastern Hungary approached us in 2022 about a complex machine line with 27 synchronised servo axes. The problem was that the servo drives used were breaking down more and more frequently. It was not possible to replace them with new devices, as they had long since ceased production, and it was possible to repair them in lucky cases, but not always. A drive failure always caused an unexpected loss of production, which upset the planned production.

1. Survey and diagnostics

The project started with a detailed site survey, during which our engineers examined the mechanical and control condition of the 27 synchronised servo axes. Together with the client, we then identified the most critical sources of failure (unreliable drives, obsolete safety systems, high control complexity) and assessed the availability and repairability of available spare parts. The result was a comparative risk and cost analysis which confirmed that a full retrofit is more cost-effective in the long term than either a continuous repair or the purchase of a new machine.

2. Technical concept and design

Our partner recognised the risk and accepted the cost comparison analysis. We then worked together to develop the technical framework for the project, which included a complete control system reconstruction.

- Selection of a new drive system and synchronous servo motors, taking into account the existing mechanics.

- Introduction of Safe-PLC to integrate security features.

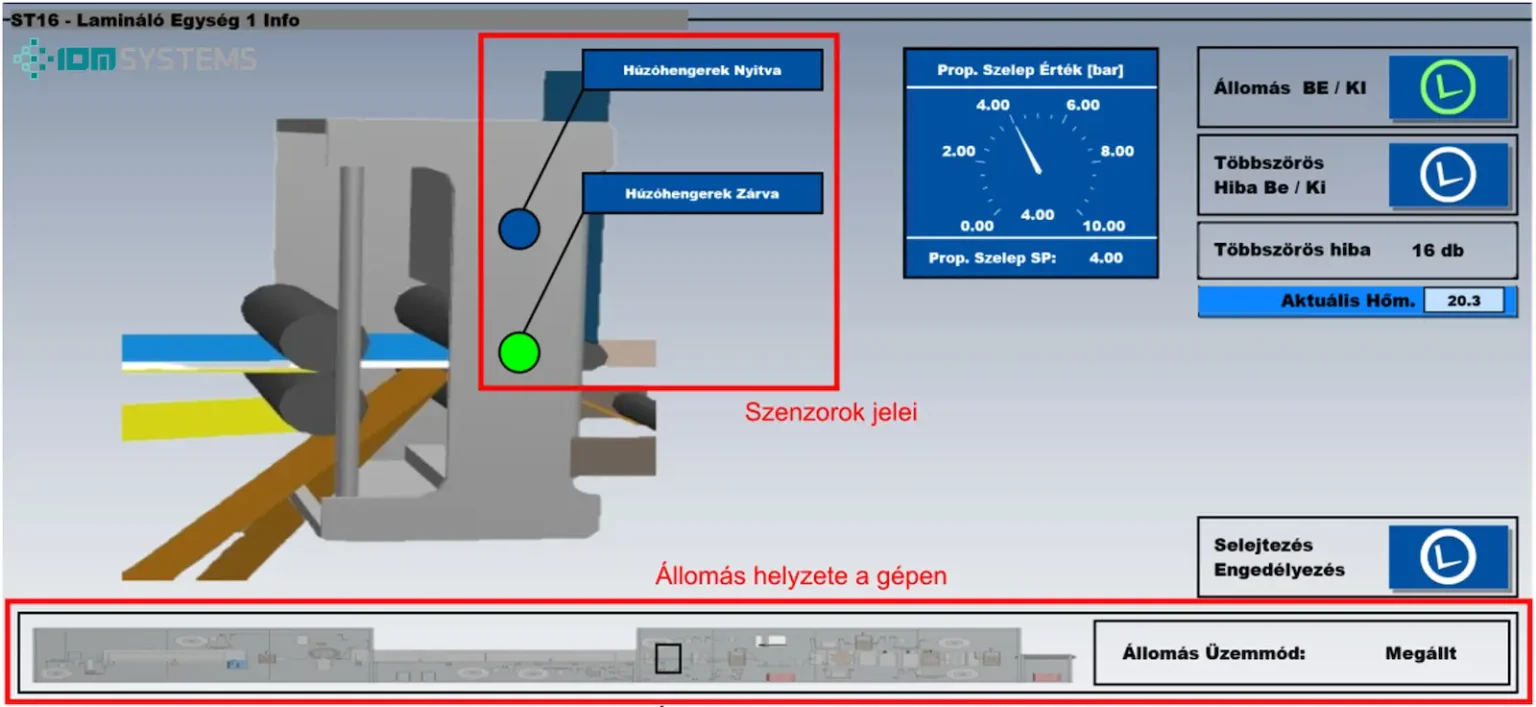

- Designing an ergonomic, uniform user interface that is compatible with the partner's other machine lines and factory standard.

- Developing a modern communication structure (Ethernet/IP) to replace the old protocols.

- Preparation for the installation of solenoid transmitters and proportional valves for finer control.

- The design included 3D CAD models, control schemes and PLC programming plans, so that the complete system could be tested before implementation.

Summary of main parameters:

Before | then | |

Control | 3pcs PLC, attached via analogue and digital interface | 1pc safe-PLC |

Safety | wired | safe-PLC and peripherals |

Communication | ASI, SERCOS, Profibus, Ethernet | Ethernet/IP (CIP-motion, CIP-sync, CIP-safe) |

3. Preparation - 12-14 months of preparation

The control cabinet, including the drives, PLC, safety modules and communication units, was prefabricated and pre-assembled. All cables, sensors and peripherals were prepared for quick installation on site. We prepared the new HMI graphic interface, incorporating the functions requested by the partner. We pre-tested the communication, drive control and safety logic in a test bench environment.

During the project, it was possible to implement new features that had become necessary as a result of decades of operational experience and which further increased the efficiency of the line (e.g. replacement of potentiometers with magnetic transmitters, installation of proportional valves). It was already clear during the design phase that the reconstruction would have to take into account the standards currently in force, particularly with regard to personnel safety solutions. The machine therefore received a new interlocking enclosure and, of course, the CE declaration of conformity was part of the project. This preparation allowed the line to be adapted to the new system with minimum downtime.

4. On-site construction, commissioning - during 10 weeks shutdown

The project timeline was structured to achieve the rebuild with the shortest possible production downtime, so after 12-14 months of offline planning, preparation, programming and pre-fitting, we were able to return the line to production after just 10 weeks of field work. During the fieldwork, we carried out continuous sub-tests, so the commissioning was easier than expected. After starting the system, we tested the different modes of the machine for several days with several types (recipes). During this time, we fine-tuned the drive parameters for optimum speed and accuracy, and customised recipe handling and maintenance functions on the new HMI.

In the last phase of commissioning, the benefits of the retrofit were already being felt:

- the new graphical interface is more ergonomic, taking into account the solutions of the other lines, thus making the allocation of operators more flexible

- some drive solutions have resulted in a much faster ramp-up of the machine, significantly reducing the amount of waste produced during ramp-up, which has been confirmed by measurements

- thanks to the modern, faster system, the machine is more stable, which also increases yields.

Both the HMI and all machine-related development environments are compatible with Windows 10/11, ensuring long-term operability and enabling remote management for future remote support.

Summary

In the end, the project delivered and exceeded expectations: the line is more efficient than ever (50% productivity increase) and all for a fraction of the cost of a new line! Operability is made easier not only by modern, future-proof components and solutions, but also by significantly reduced control complexity.

Of course, it should be emphasised that an important part of the success of a retrofit project is working closely with the operator, so that their accumulated operational and technological experience can be leveraged. In our case, this was optimally matched by the technical knowledge and technological expertise (converting domain knowledge) of IDM-Systems Zrt., so that communication within the project was seamless from the very beginning.