Goals

- Determine daily output and compare it with the 1.500-unit target.

- Map cycle times and bottlenecks in the system.

- Analyse the operation of the automated Bosch TS2 conveyor.

- Examine the impact of different configurations (number of operators, robot gripper, motion logic).

- Define the theoretical maximum capacity of the line and equipment, and assess how it depends on production conditions (e.g., machine availability, maintenance cycles, quality scrap rate, operator performance).

Challenges

- Forecasting performance before the production cell is built.

- Coordinated modelling of automated and manual stations.

- Locating potential bottlenecks and identifying their causes.

- Analysing pallet congestion behaviour at the beginning and end of the conveyor.

Solution

- Discrete-event simulation model built in Siemens Plant Simulation.

- Incorporation of the real and planned layout and operating logics.

- User-friendly GUI with easily adjustable parameters.

- Execution of multiple scenarios (e.g., different station cycle times, operator counts, robot gripper types).

- Online consultations for continuous model refinement.

Results

- Base case: 1.740 units/day → +16% versus target.

- Worst case: 1.545 units/day → still +3% versus target.

- Successful identification of bottlenecks.

- The dual robot gripper increased performance only in certain cases.

Challenge: Analysing a production cell using a simulation model

During the design of the production cell, it was crucial to forecast expected performance accurately, analyse system cycle times, identify potential bottlenecks, and understand pallet congestion at the start and end points of the automated conveyor. The goal was to give the client a clear picture of the cell’s behaviour under various conditions before implementation. The simulation also focused on the maximum capacity achievable by the given line and asset base under ideal conditions, and how this capacity depends on production factors such as machine availability, maintenance cycles, fault rates, quality scrap rate, and operator performance.

Project objective: Validate performance, propose modifications

Main objectives:

- Determine achievable daily output and compare it to the planned 1.500-unit target.

- Analyse system cycle times.

- Map bottlenecks within the production cell.

- On the automated section, analyse the Bosch TS2 conveyor operation: stopper behaviour, sensor input times, other delays.

- Evaluate the impact of varied configurations (e.g., fewer operators, modified motions and tasks).

Further investigations targeted system sensitivity and robustness:

- Effect of availability levels: modelling machine stops, maintenance cycles, fault rates.

- Effect of quality scrap rate: impact of higher scrap on daily output.

- Energy consumption and cost optimisation: energy demand and cost-effectiveness of different configurations.

- Operator workload: human-factor impact on cycle time and error rate.

- Flexibility analysis: system response to unexpected events (e.g., machine failure, raw-material shortage).

- Product variance handling: producing different product types in the same cell; effect of changeover times.

- Logistics interfaces: impact of material supply and removal on cell performance.

Solution: Build, validate, and analyse the simulation

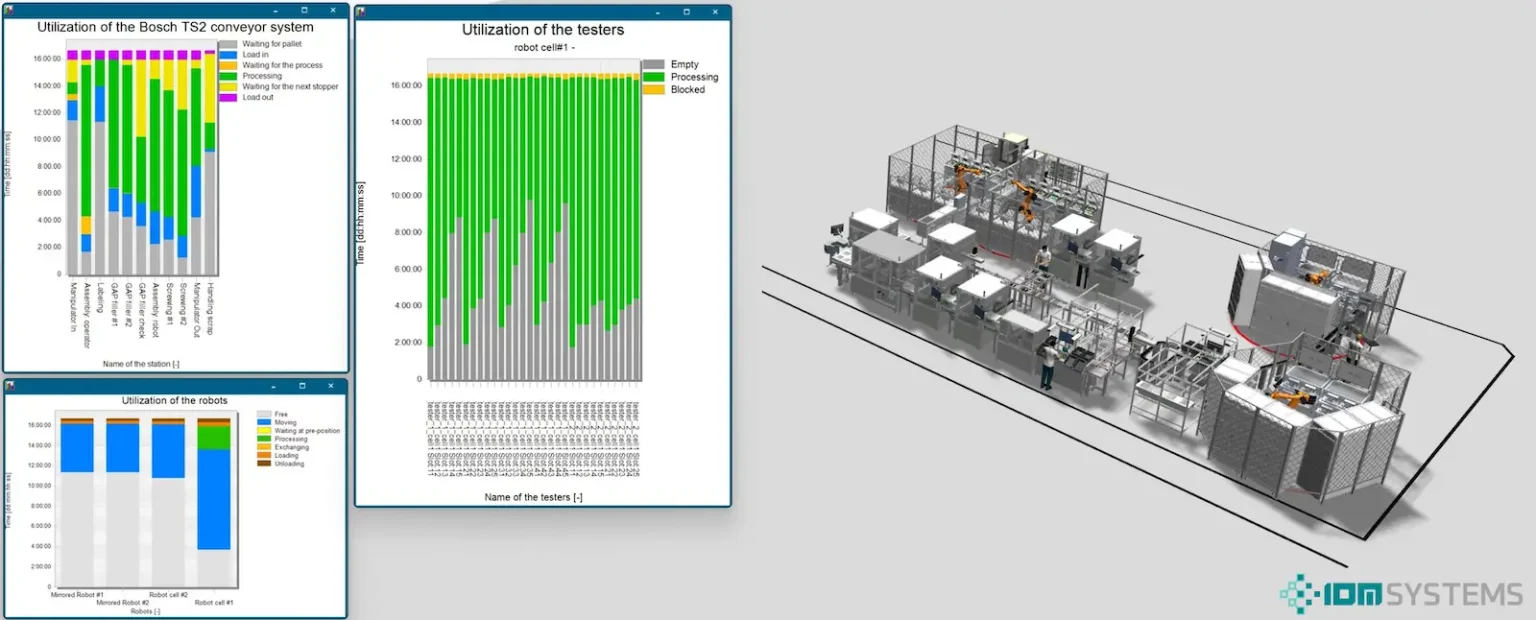

We modelled the entire production cell in Siemens Plant Simulation. The model included manual workstations and operators, the automated Bosch TS2 conveyor system, robot cells, testers, and a cooling tunnel. Layout and operating parameters were based on client data, while continuous online consultations ensured logic fine-tuning.

Key characteristics of the simulation:

- Discrete-event simulation (DES).

- Application of real/planned layout and operating logics.

- Joint modelling of manual and automated sub-systems.

- User-friendly GUI with easily adjustable parameters.

- Multiple scenarios to test operating variables.

Analysis and evaluation

We ran multiple scenarios. Examples:

| Scenario | Cyle time (s) | Bottleneck |

| Base case | 49,70 | Tester A |

| Tester A cycle time – 42 s | 57,00 | Tester A |

| Tester B cycle time – 30 s | 49,25 | Roundtable |

| 2 operators (instead of 3) | 55,85 | Operator #2 |

Additional cases:

- Separate pick-up and drop-off positions: no impact on results.

- Dual robot gripper: increased daily output only when Tester B was the bottleneck.

Results: Making well-founded decisions

In the base case, the system achieved 1.740 units/day, significantly exceeding the target. Even in the worst scenario, 1.545 units/day was reached, giving the client confidence that the planned target is achievable.

The simulation highlighted that the main bottlenecks are not always in the most obvious places: Tester A and the rotary table played a key role in performance. A dual gripper on the robot increased productivity only when the robot itself was the bottleneck; otherwise, it had no effect on the cell’s overall output.

Solution and conclusion

The model enabled evaluation of the production system before implementation. Based on the simulation, we proposed optimisations such as tester allocation, fine-tuning of cycle times, and defining the number of operators.

Key takeaways:

- Bottlenecks are not always where you’d first expect.

- Robot-system upgrades (e.g., dual grippers) do not always improve output—even if the bottleneck is within the robot cell.

- A DES model is an excellent decision-support tool, even in the design phase.

Why was this project outstanding?

Why was this project outstanding? In this project we simulated a complex (manual and automated) system, examining not only performance but also sensitivity across scenarios. Collaborative thinking and iterative modelling enabled the development of a highly accurate simulation and, consequently, a robust evaluation of the results.

Summary

A simulation project like this—tied to a production cell—is an excellent example of how discrete-event simulation can support production planning and decision-making. Thanks to thorough modelling and well-designed scenario analysis, the future production line can be realised in an optimised, well-prepared form.