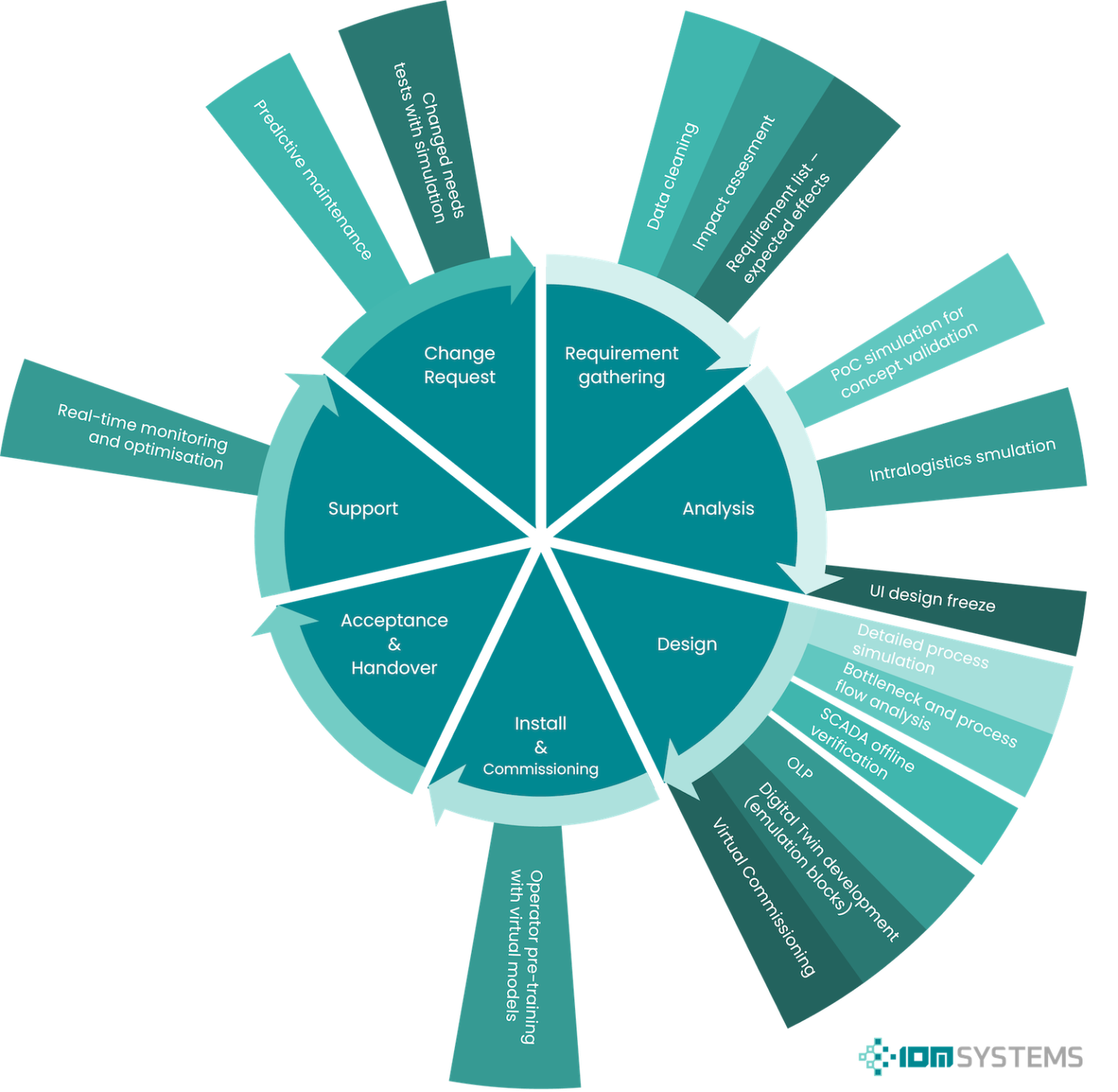

Industrial digitalization is not just a technological trend – it is a strategic tool that can reduce costs, increase productivity, and accelerate market entry.

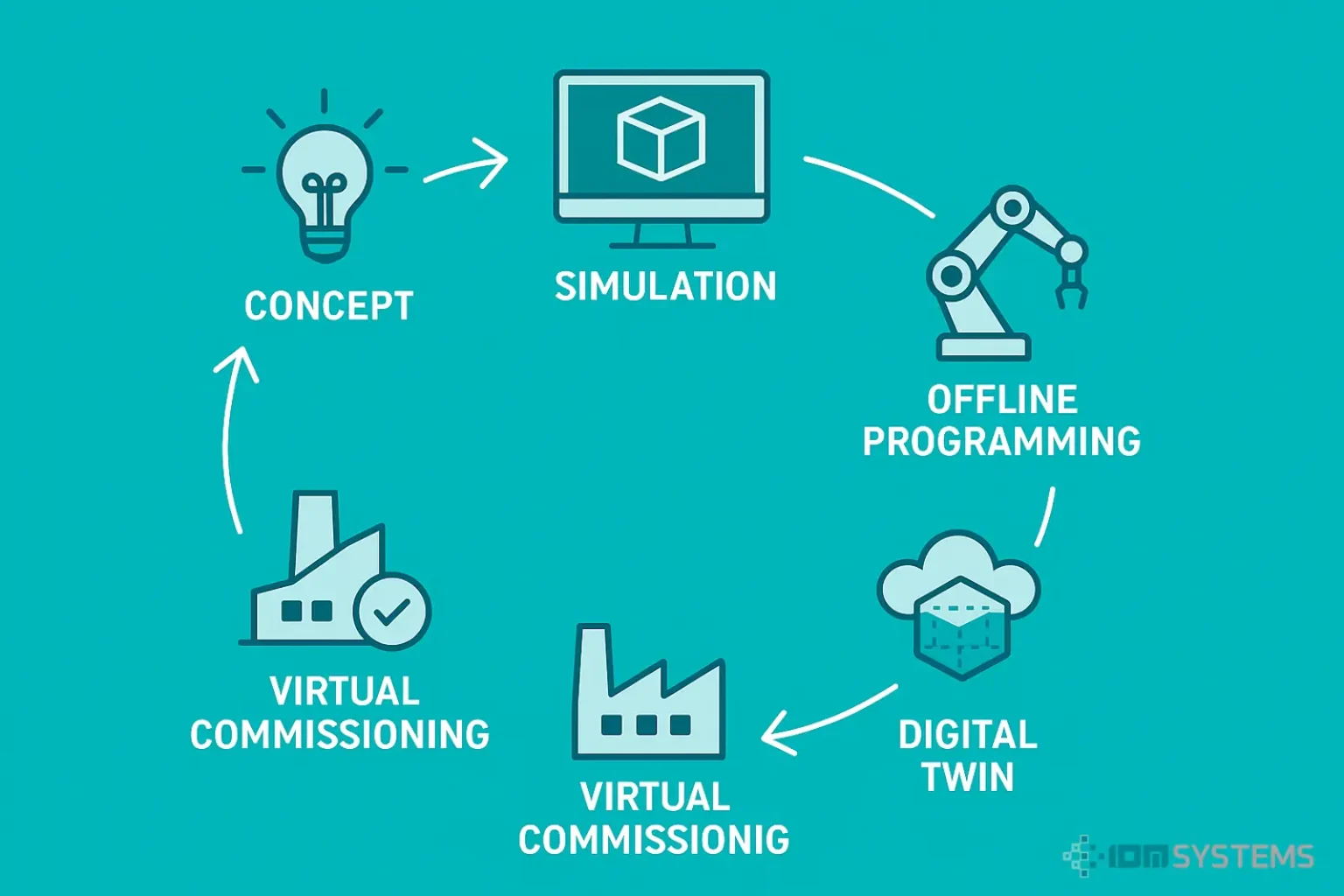

Our team of engineers takes projects from concept to working system: from simulation through virtual commissioning to digital twins. So our customers can see how their system will work at the design stage - and avoid costly mistakes.

We implement industrial digitalization solutions in our own projects and as independent assignments, even in the form of complex consulting services.

Our areas of expertise – where digital technology meets reality

Concept design and PoC (Proof of Concept) simulations

- Defining project objectives, technological basis and requirements

- PoC simulations to demonstrate feasibility

- Quick validation before a single screw is put in place

- Layout design and simulation (Logical, 2D, 3D)

Detailed simulations - Siemens TX Plant Simulation, Process Simulate

- Modelling the operation of complex systems

- Investigating bottlenecks, real cycle times and component interactions

- Design and optimisation of automation logic and control adapted to real-world conditions

- Pre-investment ROI simulations

- AGV / AMR simulations

- Material flow simulation

Offline Programming (OLP)

- Programming robots and automated systems in virtual environments

- Faster start-up, less downtime, more accurate operation

Development of emulation systems

- Virtual modelling of the behaviour of hardware and software devices

- Hardware independent testing of PLC logic and controls

Virtual commissioning - SIMIT, PLC Sim Advanced, Siemens NX MCD, Plant Simulation, Process Simulate, Visual Components

- Testing and optimisation before the production line starts

- Reducing the time and cost of on-site testing

- Particularly effective brownfield projects, but also for greenfield investments

- Faster deployment, lower risk

Operational support with digital twins

- Predictive maintenance and energy optimisation

- Real-time monitoring and continuous optimisation

- Developing sustainable, efficient production systems

Advice based on industrial digitalisation methodology

- a process of defined steps, starting with a thorough assessment,

- 4 stages for the production concept creation: PoC, Layout, 3D simulation, Masterplan

- Practical training on real industrial tools and digital models, in classroom and online

- Using digital techniques: using and creating models of your own design

- Complete production simulations for safe, effective training of operators, maintenance staff and programmers using digital twin pairs

What do you gain with us?

Our digital solutions give you an accurate picture of how your system is working, from design to operation - so you can reduce risks and optimise your processes.

- Less risk - detecting errors at the design stage

- Faster implementation - shorter downtimes through OLP and virtual tests

- Sustainable operations - digital twins and continuous optimisation

- Better collaboration - better communication between departments through simulations

- Predictable costs - more accurate planning, fewer surprises

- Optimising existing systems - we map the optimum of current operations, anticipate expected demands and make production resilient to future capacity challenges

- Validate new systems - get an accurate picture of how processes work at the design stage, so the system is efficient at start-up

- Data-driven decisions - through simulations and digital twins, decision-making is based on real data, not assumptions

Our team

Our engineers use real-world industry experience and up-to-date knowledge to turn simulations and models into working manufacturing systems. We combine digital technology knowledge with traditional but high-level domain expertise, so that the result is not just a simulation demonstration, but a complex answer to manufacturing questions and problems.

- Mechanical engineers, structural engineers - people who understand technology

- Robot programming specialists - with high-tech experience

- PLC and automation experts - in optimising complex systems

- Digital twin and simulation engineers - anticipating the future of the factory

With us, digital technology delivers tangible business results!

We design in computer models what will later become reality on your production line - faster, with fewer errors and more predictable costs.

- Let's finance your industrial digitalisation project together!