Projectname

DITAC (DIgital Twin for Agile Changes): implementation of a digital twin-based solution to support rapid redesign and modification of industrial automation systems, especially for post-change requirements.

Participating partners

- Restart Srl (Italy) - designer and manufacturer of industrial automation systems, end user of the project. [restart.it]

- IDM-Systems Zrt. (Hungary) - developer of digital models, simulation environment and virtual commissioning. [idm-systems.hu]

- CNR-IMATI (Italy) - developer of machine learning models and expert in digital twin-based predictions. [imati.cnr.it]

Motivation

Restart Srl. develops customised industrial automation solutions, but the end-user's need for subsequent modifications (e.g. integration of a new product into existing production) requires significant machine modifications and thus downtime. These modifications not only consume a lot of resources, but also often lead to extended production downtime.

Previously, design was limited to mechanical modelling (e.g. using SolidWorks), with no link between the physical processes and the control software (PLC). DITAC's goal was to create a digital twin-based solution that would allow preliminary virtual testing of modifications, reducing the time and resources required for real modifications.

Another advantage of the new environment is its predictive capabilities to ensure the stability and quality of manufacturing processes, both by early detection of unforeseen process changes and by predicting leakage test.

The aim of the development

The DITAC project aimed to digitalise Restart’s mechatronic systems to turn them into full cyber-physical systems (CPS). This involved using Siemens Tecnomatix Process Simulate to create the kinematic model from the existing 3D CAD models, while the PLC programs were emulated in the Siemens SIMIT environment, creating the "control digital twin".

The two environments are connected via a standard interface, allowing integrated simulation of machine movements and control logic.

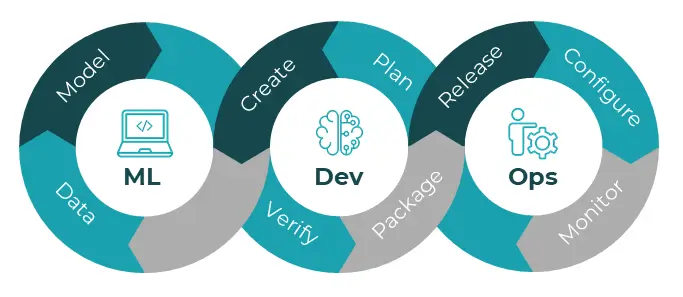

This was coupled with a machine learning model with two independent predictive functions:

- Press process prediction: the model detects unforeseen production changes (for example, if the cable, the sensor or any of the components involved in the press deviate from the usual behaviour). These signals allow timely detection, so that intervention can be made before the actual failure occurs.

- Leak test prediction: based on the pressing and twisting curves, the model can predict if a product is likely to leak. Since the helium leakage test is slower than the manufacturing process itself and the test material is extremely expensive, this solution allows defective parts to be filtered out before the physical test, saving significant cost and resources.

Finally, the solution runs on a cloud-based platform, integrates with other systems via open APIs and can be easily deployed on new machines or cells. Among the software used are Siemens Tecnomatix, SIMIT, Simatic Manager, and the machine learning model wrapped in a Docker container.

Expected technological impact

Two digital twins for Restart production cells were successfully created during the project, demonstrating the partners' competence for similar future projects.

The main technological achievements:

- A safe test environment for validating PLC and robot programs before real installation.

- Customized simulation libraries (SIMIT, Process Simulate) for Restart standards.

- A reliable ML model for predicting press failures.

- Reliable ML model for early detection of unforeseen changes in the pressing process, allowing intervention before failures and prevention of unplanned downtime.

- ML model for predicting leakage risk, using pressing and torque curves, reducing the number of costly and slow helium tests.

- Full virtual commissioning environment with integrated process and control simulation.

- Reusable process models and libraries that can be used on other machines.

The result is a scalable, cloud-based solution that accelerates the introduction of new machines, reduces errors and supports predictive maintenance.

Expected economic impact

There will be significant economic benefits for industrial partners and end-users:

- This significantly reduces the time and cost of on-site work and machine downtime.

- Shorter changeover times reduce downtime and production losses.

- Pre-testing PLC programs reduces the risk and stress of actual commissioning.

- Remote FAT testing is possible, which makes the customer approval process faster.

- Software quality improves and the number of warranty repairs decreases.

- By predicting the pressing process, unplanned failures can be avoided, resulting in direct cost reductions and increased productivity.

- Predicting the leakage test avoids expensive and slow helium testing, which saves significant resources.

- Predictive maintenance reduces the loss of revenue due to unplanned downtime.

- Reducing scrap also delivers environmental benefits.

- Virtual commissioning is especially cost-effective for high-value, custom machines.