Goals

- Simplify and speed up manual data entry and type change

- Automating, robustifying and accelerating the transshipment process

- Accurate and automatic recording of production data

Challenges

- Production efficiency and product quality were not monitored on a data basis

- Production processes were not uniform, varying from one site to another

Solution

- Delta robot integration with real-time camera positioning

- Camera-based quality control system for automatic detection of defective products

- Customized HMI and control PC supporting production with image processing and recipe management

- Barcode-based recipe changeover with PLC-based control to minimise the potential for error

Results

- Significant growth in production capacity, as the system operates without interruption

- Up to 8.000 - 15.000 € material and energy savings by reducing incorrect transshipments

- 5000 - 10.000 € savings in maintenance costs due to continuous operation and lower maintenance requirements for the robotic system compared to the devices associated with the manual workstation

- 25000 - 50.000 € in losses prevented, as the system avoids downtime and the accumulation of scrap.

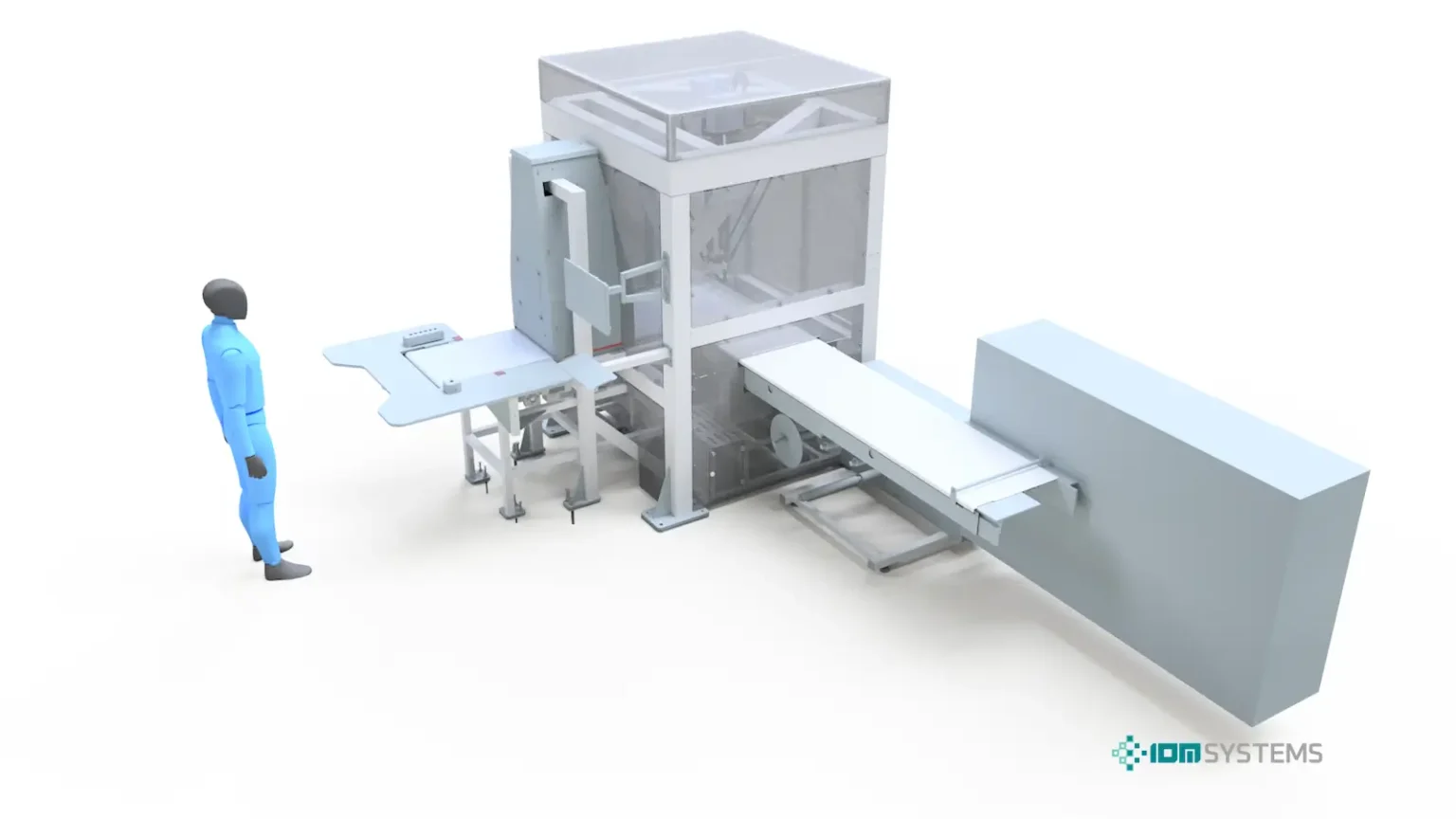

High speed, precision material handling in a compact system

The key to modern manufacturing environments is fast, accurate and intelligent material handling and control. In our latest development, we have installed a camera-based quality control and transfer system based on a Delta robot at an international pharmaceutical company's site in Hungary.

The automated system carries out a camera inspection as the products move along the conveyor belt, and the robot then places them in a precisely defined position - or removes the defective pieces. The solution is particularly well suited to the food, pharmaceutical and general manufacturing sectors, where optimisation of consistent product quality and cycle times is critical.

Process overview

The system works as an in-line process, where workpieces pass through the following steps without interruption:

- Camera control: The workpieces on the infeed conveyor are checked by a high-resolution camera to determine whether they meet the quality requirements.

- Positioning on the move: The delta robot uses camera and encoder data to accurately locate and pick up moving workpieces.

- Transshipment or scrap handling: The robot places the parts in the predefined positions according to the high precision required by the packaging of the products - or automatically removes them from the system in case of a defective product.

Advantages of the solution

- Efficiency - high speed and accuracy: the robot can pick up and unload workpieces in motion, so there is no need to stop the conveyor belt. The high speed of the delta robot means that the packing runs efficiently.

- Compact design: the suspended delta robot requires minimal space and can be easily integrated even above existing production lines.

- Flexibility: can be used with interchangeable grippers for different products.

- Wide range of industrial applications: suitable for loading, transfer and packaging processes.

Typical application areas

- Quality control and scrap management on the infeed side of packaging machines

- Transfer control station between production line and packaging machine

- Automatic unit-crate packing at the end of production lines

Target sectors

- Manufacturing industry

- Food industry

- Pharmaceutical industry

Key elements of the system

- high-speed ABB delta robot with interchangeable, coded grippers and quick tool change

- infeed conveyor with Basler camera control with integrated LED lighting and polarised filters

- integrated recipe management for fast type changeover with user rights management

Results and business benefits

- Non-stop production: no need to stop the conveyor, reduced cycle time, improved efficiency.

- Reduced reject rate: automated camera quality control eliminates human error.

- Less operator intervention: improved ergonomics and process safety.

Summary

This development will bring a new level of automation to workpiece handling and quality control on site. The modular, customisable system is designed to provide our partners with a reliable and sustainable solution for the production lines of the future - today.