OEE statement - agribusiness case study

Measurement of the efficiency of seed plant drying chambers. The aim is to collect and evaluate current data for harvest scheduling and to analyse data collection for long-term decisions.

Measurement of the efficiency of seed plant drying chambers. The aim is to collect and evaluate current data for harvest scheduling and to analyse data collection for long-term decisions.

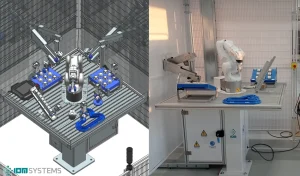

A new automotive factory in Eastern Hungary has ordered industry-standard robotic training cells from IDM-Systems Zrt. to support efficient training of its employees. The aim of the project was to ramp up production as quickly as possible by pre-training factory workers.

In just 10 weeks of downtime, we gave a 27-axis production machine a new lease of life: a complete control system overhaul, a modern servo drive system, an ergonomic HMI and state-of-the-art safety solutions - for a fraction of the price of a new production line.

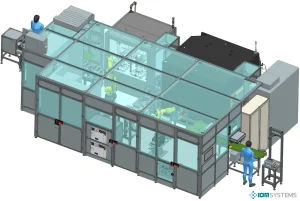

For a TIER3 automotive supplier, we have developed a fully automated final inspection cell integrating multiple test and inspection stations, capable of handling up to five different product types. The system provides full product tracking, detailed measurement data backup.

In Tatabánya, we implemented an energy-efficient drive technology modernisation for the high-bay warehouse stackers of a logistics centre. The installation of a new generation of energy-recovery frequency inverters significantly reduced electricity consumption.

Our digital manufacturing technologies have resulted in faster commissioning, shorter cycle times, cost reductions and satisfied customers throughout the lifecycle of one of our completed machine building projects.