Modernise your existing equipment with state-of-the-art control and drive technology! Increase reliability, reduce errors and prevent unexpected downtime. This is retrofit thinking.

We strongly advise you not to wait for the moment when you need to find an SOS solution!

What do we offer?

The experts at IDM-Systems Zrt. offer a range of services to help their manufacturing partners avoid unexpected catastrophic failures:

- machine assessment, component life cycle checks, identification of trigger products,

- design and implementation of complete machine overhauls, both from the mechanical and drive automation point of view,

- education and long-term support

We help our partners to keep their machines running at high efficiency for as long as possible, and we anticipate when major intervention is required.

Modernisation is inevitable throughout the life cycle of industrial machinery and systems to keep up with modern production and energy efficiency requirements. The retrofit solutions of IDM-Systems Zrt. allow you to economically upgrade your existing equipment by integrating the latest drive technology and automation devices.

Why is a retrofit worth it?

- Productivity increase: up to 30-50% capacity increase through modern controls and optimised drive technology (cycle time improvement - speed increase, ramp-up time reduction, faster product changeover, scrap reduction)

- Energy efficiency: newer electronic industrial equipment has lower energy demand and energy losses than older equipment, e.g. by using regenerative drive technology, energy savings of up to 30% can be achieved

- Ensuring parts supply: replacing obsolete, discontinued parts with affordable and long-term supported solutions

- Reducing maintenance costs: modern systems offer lower failure rates and easier maintenance, and are often more affordable than discontinued or aftermarket counterparts

- Reducing maintenance time: modern parts are available with shorter delivery times

- Diagnostics: the use of modern electrical tools allows for advanced machine diagnostics

- Digital monitoring and data analysis: the possibility to integrate IIoT and predictive maintenance functions

- Machine safety and cyber security/NIS2 compliance: machines equipped with new devices, but otherwise still technologically sound, comply with the latest industry regulations.

Our reference projects in retrofit operation

- Modernisation of drive systems from Lenze, Allen-Bradley and Siemens

- Retrofit of a 27-axis industrial machine: following the modernisation, the productivity of the machine has increased significantly, downtimes have fallen significantly.

- Regenerative propulsion applications: advanced propulsion systems have reduced the overall energy consumption of the system by 30%, while the operation become more stable, dynamic and reliable.

With us, digital technology delivers tangible business results!

We design in computer models what will later become reality on your production line - faster, with fewer errors and more predictable costs.

- Let's make your industrial processes more efficient together!

Detailed description

It is in the interest of every manufacturing company to have an efficient fleet of machines. The three pillars of efficiency are availability, productivity and low scrap rates.

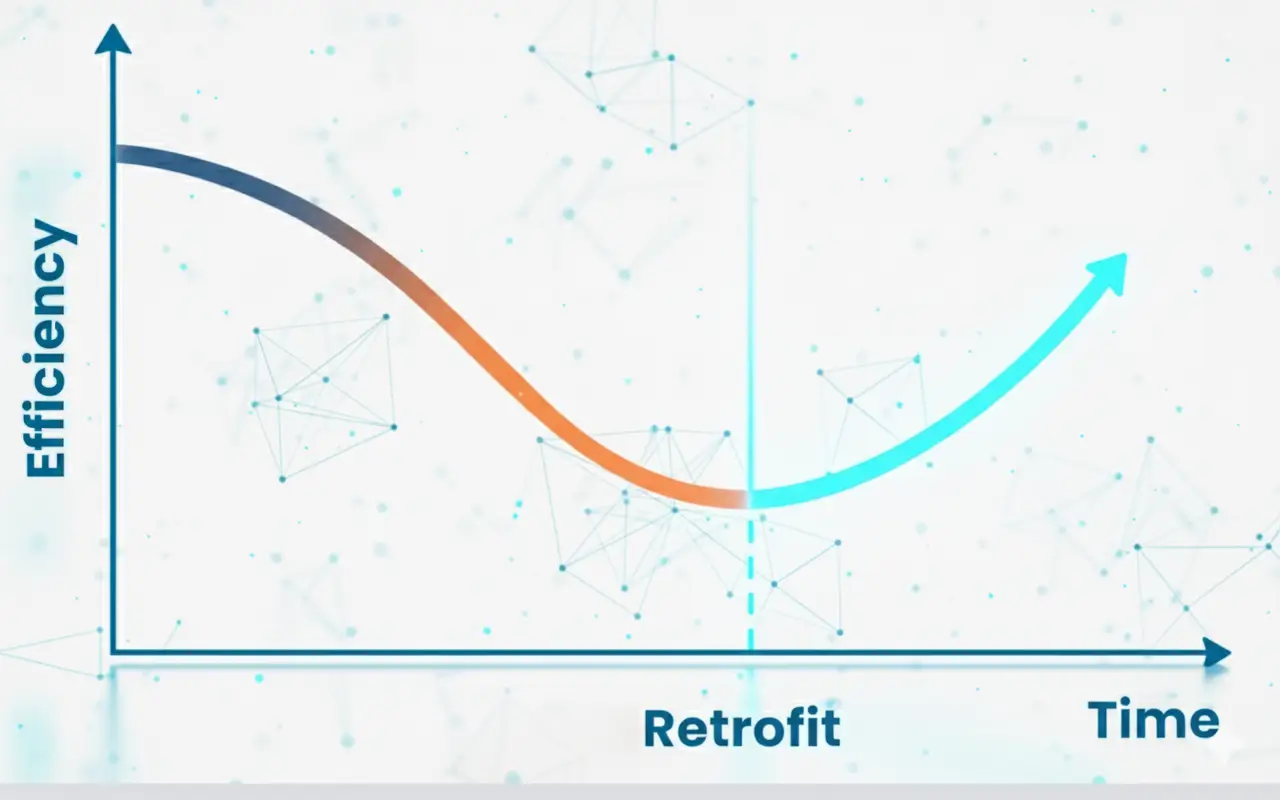

The ageing of manufacturing machines over time has a negative impact on all three aspects:

- mechanical wear reduces precision, entails more frequent repairs and reduces production speed,

- the ageing of electronic components erodes their availability, failures become more frequent and eventually replacements become impossible.

- some old, outdated devices often do not stop working straight away, but can be unpredictable.

This process is slowly eroding production efficiency over decades. It may not be visible when evaluating daily production reports, but its impact is certainly visible in a 10-20 year time horizon.

Particular attention should be paid to those control components that have reached the end of their production life cycle and are not available as spare parts. This in fact implies that more and more components have to be considered as critical components, especially if a 1:1 replacement is not possible with newer generation devices. In any case, frequency converters, PLCs and HMIs deserve special attention.