Goals

- Creation of a fully automated production cell for the inspection, marking and transfer of parts after heat treatment.

- Integration of third party machines (helium leak tester, CT equipment) into the process.

- Product tracking per station, detailed measurement data backup to MES and SQL.

- Flexible operation for multiple product types with a simple changeover process.

Challenges

- Coordinate several different manufacturing and measurement processes within a single cell.

- Reliable communication and control of third party equipment (helium leak tester, CT, measurement systems).

- High-precision geometric inspection of medium-sized products using 3D point cloud fitting.

- Ensuring full traceability at station and product level, with MES integration.

Solution

- PLC and HMI control: Siemens S7-1500 PLC and COPA-DATA Zenon based HMI.

- 3D measuring system: system based on LMI Gocator 2530 lens scanners (6).

- full integration of 3rd party equipment.

- Traceability: per-station product tracking, communication to MES and SQL.

- Flexible product changeover: a process optimised for fast tool and product type changeovers.

Results

- Expected cycle time 17-24 seconds/product depending on type.

- Optimising labour requirements: 2 operators and optionally 1 technician are needed for the daily operation of the cell.

- Quality assurance improvement: 100% product tracking and measurement data backup.

- Cost reduction: annual savings of around €120,000 by reducing labour and scrap.

Detailed description

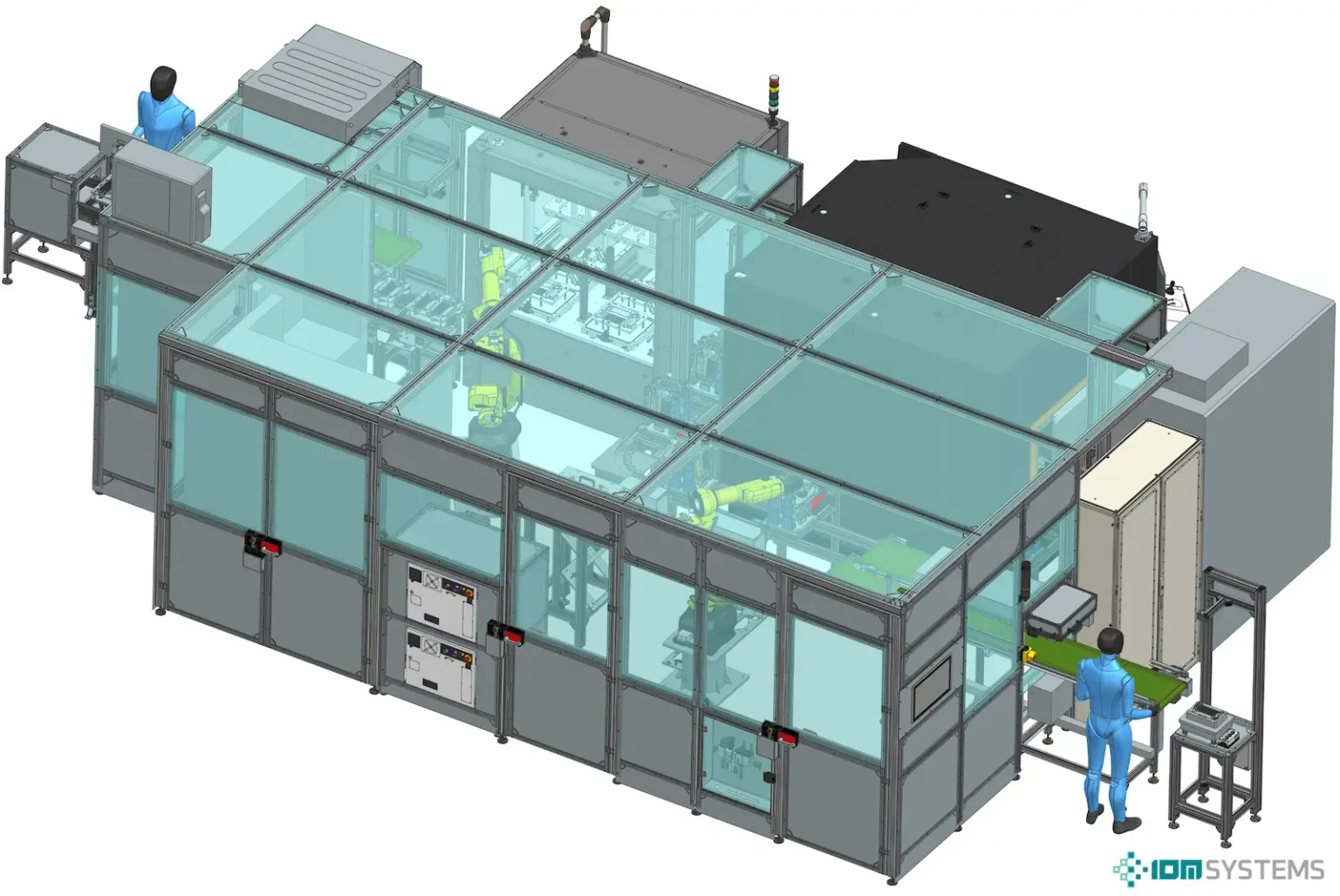

We were approached by a leading TIER3 automotive supplier with a complex requirement to design and install a turnkey, fully automated End Of Line (EOL) inspection cell at their Győr site. The aim of the project was to create a flexible, robust and reliable system capable of handling 5 different product types, ensuring the highest quality requirements are met whilst minimising cycle time and labour requirements.

The system had to be able to meet the following strict criteria:

- Multi-stage verification: The cell had to be capable of helium leak testing, CT scanning to examine the internal structure of the product and highly geometrical measurements to measure external product characteristics.

- Flexibility: The machine had to be designed to handle 5 different product types, with cycle times adapted to the specific product type. In addition, the integration of helium leak detection and CT equipment from German suppliers was also part of our tasks.

- Traceability and data management: The data of every single product manufactured had to be accurately tracked (per station), recorded and stored (in MES and SQL database), including measurement parameters, DMC codes and OK/NOK results.

- Minimalist treatment: The cell had to be able to be operated efficiently by a maximum of two operators, with an additional technician needed for day-to-day operations.

- Maintenance and type change: The changeover process needed to be accelerated to allow a 10-15 minute window of time to make the changeover between types.

The stages of implementation

IDM-Systems completed the task fully relying on its own software development team and in a very efficient way. With the unique combination of the S7-1500 PLC and the COPA-DATA Zenon-based HMI system, we not only met the customer's basic requirements, but also provided the system with a number of valuable extra features to make production run more smoothly.

One of the keys to the success of the project was careful planning and simulation. The development of the PLC code optimised by virtual commissioning (using a combination of Process Simulate and SIMIT software), and HMI-PLC communication was fully tested prior to installation on site. This approach significantly shortened the on-site commissioning time and minimised the risk of potential failures.

Customized HMI (Zenon):

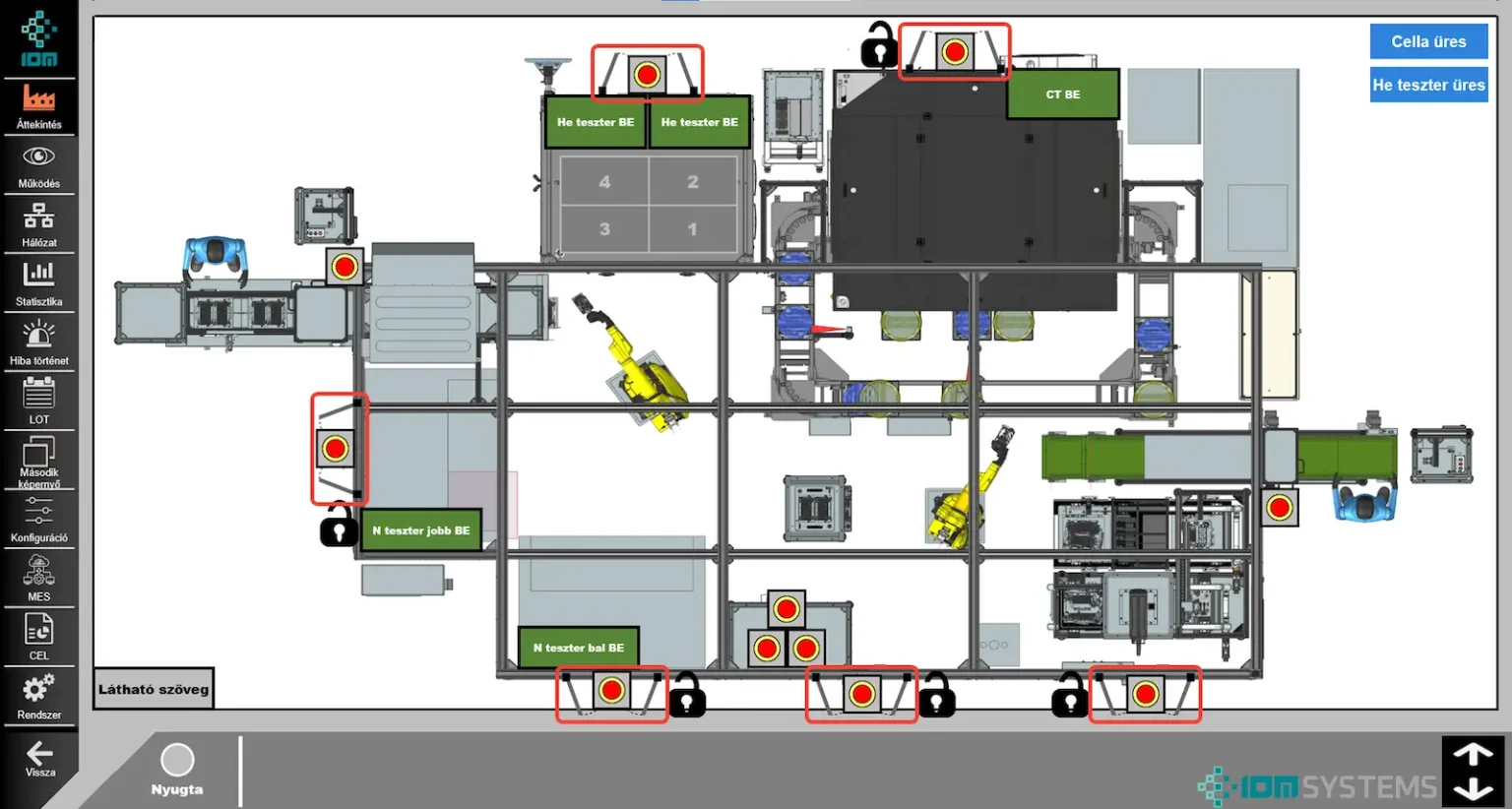

- Through the user-friendly Zenon HMI interface, custom developed by IDM-Systems, operators can intuitively monitor and control the entire cell.

- The HMI enables traceability of products, real-time display of statistical data and the setting of various parameters based on user rights.

- External measuring stations (helium and CT) can be activated or deactivated via the HMI, providing maximum flexibility for different test procedures.

- Special modes have been programmed to calibrate the measuring equipment and make the production process more ergonomic for operators.

Integrated Image Processing and Robotics:

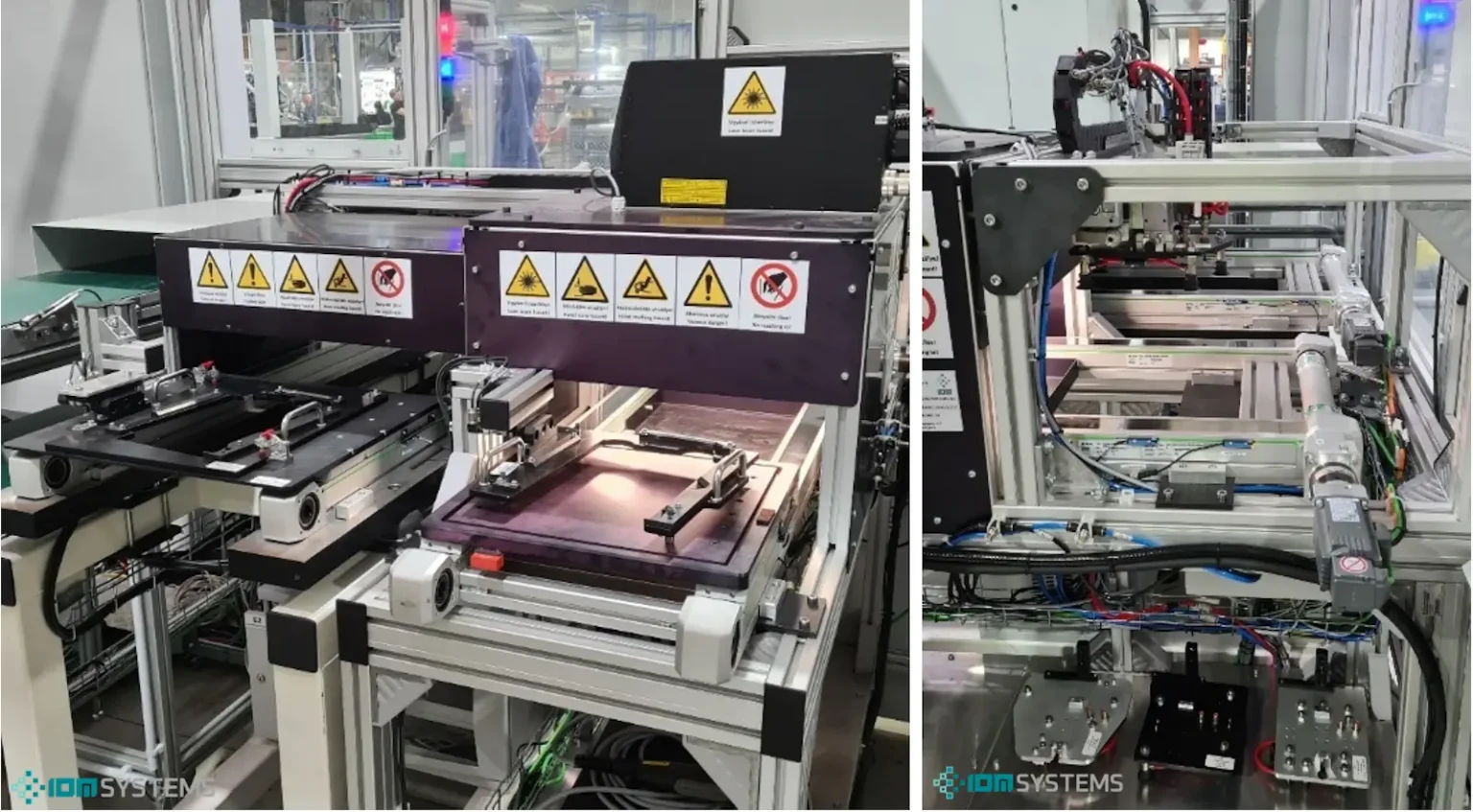

- IDM-Systems' proprietary 3D measurement system was integrated into the cell. This system consists of 6 Gocator 2530 line scanners, which can be used to create a uniform point cloud of even medium-sized parts for precise geometric measurement. During software development, we stitched the images from the scanners together to inspect the entire surface of the products. In addition to the geometric dimensions (product length, hole diameter, hole position relative to the base, etc.), various shape properties are also measured (flatness, undercut, etc.).

- In the cell, 2 industrial robots of the FANUC M-10 series perform pick-and-place tasks. For accurate and stable packing, spiked product placement is preferred, and the products loaded by the operators are packed by the robots according to the offset calculated by the Keyence VS camera.

- We have also integrated the DMC code recognition system, which can reliably recognise DMC segments up to 0.35 mm, ensuring product traceability.

Data Management and Traceability:

- The cell incorporates a station-by-station product tracking system, which ensures that the journey and test results of each product can be tracked.

- All relevant data of the machine (leak and CT test results, geometric measurements, DMC codes, etc.) are automatically saved in the MES system and SQL database. This robust data management is essential for quality assurance and optimisation of production processes.

IDM-Systems' expertise provided the customer with a system that not only meets the specified cycle times and labour requirements, but is also ready for future expansions and changes in production needs. Through our software solutions, virtual commissioning and dedicated HMI functions, the machine operates extremely efficiently and reliably. With the successful integration, including third-party equipment, the client has significantly increased its production efficiency and quality assurance capabilities, laying a solid foundation for future growth and further development.