Goals

- Create a realistic model of the entire production process at the seed-processing plant.

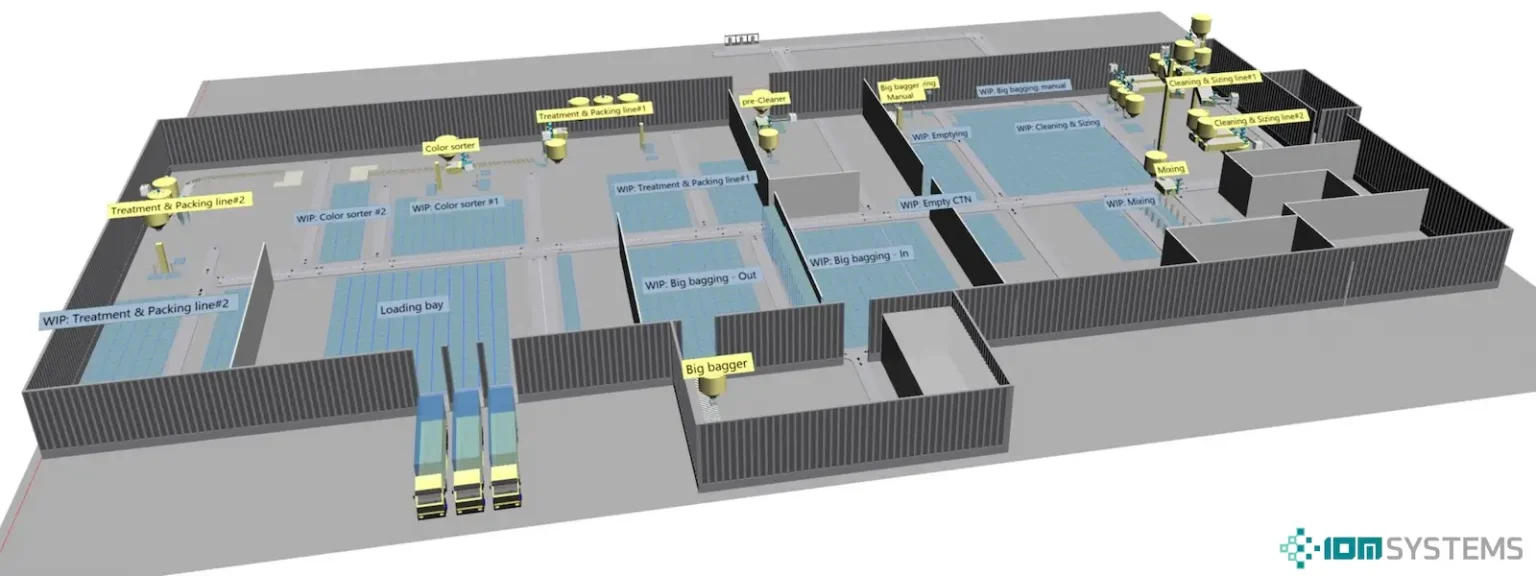

- Precisely model the operation and capacity utilisation of WIP buffers.

- Pre-test scheduling scenarios using real data.

- Simulate dynamic material flow using Fluid Library elements.

- Provide decision support for daily production planning and reduce risk.

- Ensure flexibility for season- and weather-dependent processing of different seed varieties.

Challenges

- Accurately mapping a complex production process that includes continuous material flow and WIP buffers.

- Direct import and simulation replay of scheduling plans.

- Ensuring validation against real processes.

- Handling large data volumes.

- Modelling capacity peaks and congestion arising from seasonal, weather-dependent harvesting.

Solution

- Development of a Siemens Plant Simulation model using the Fluid Library.

- Site visits, online consultations, and structured data collection about real plant operations.

- Realistic modelling of WIP capacities, locations, and material flow.

- Automatic import and simulated execution of production schedules.

- Model validation against the plant’s historical performance data.

- The model can handle differing maturation times of seed varieties and seasonal processing peaks.

Results

- The model reduced scheduling errors by more than 30%.

- By minimising production risks, it became possible to avoid annual losses of tens of thousands of euros.

- Daily scheduling decisions can be made quickly and objectively.

- Rapid identification and elimination of weak points (congestion, overloaded sections).

- Forecasting seasonal processing needs led to more balanced capacity utilisation and better handling of harvest peaks.

Challenge: Simulating a whole factory and analysing improvement options

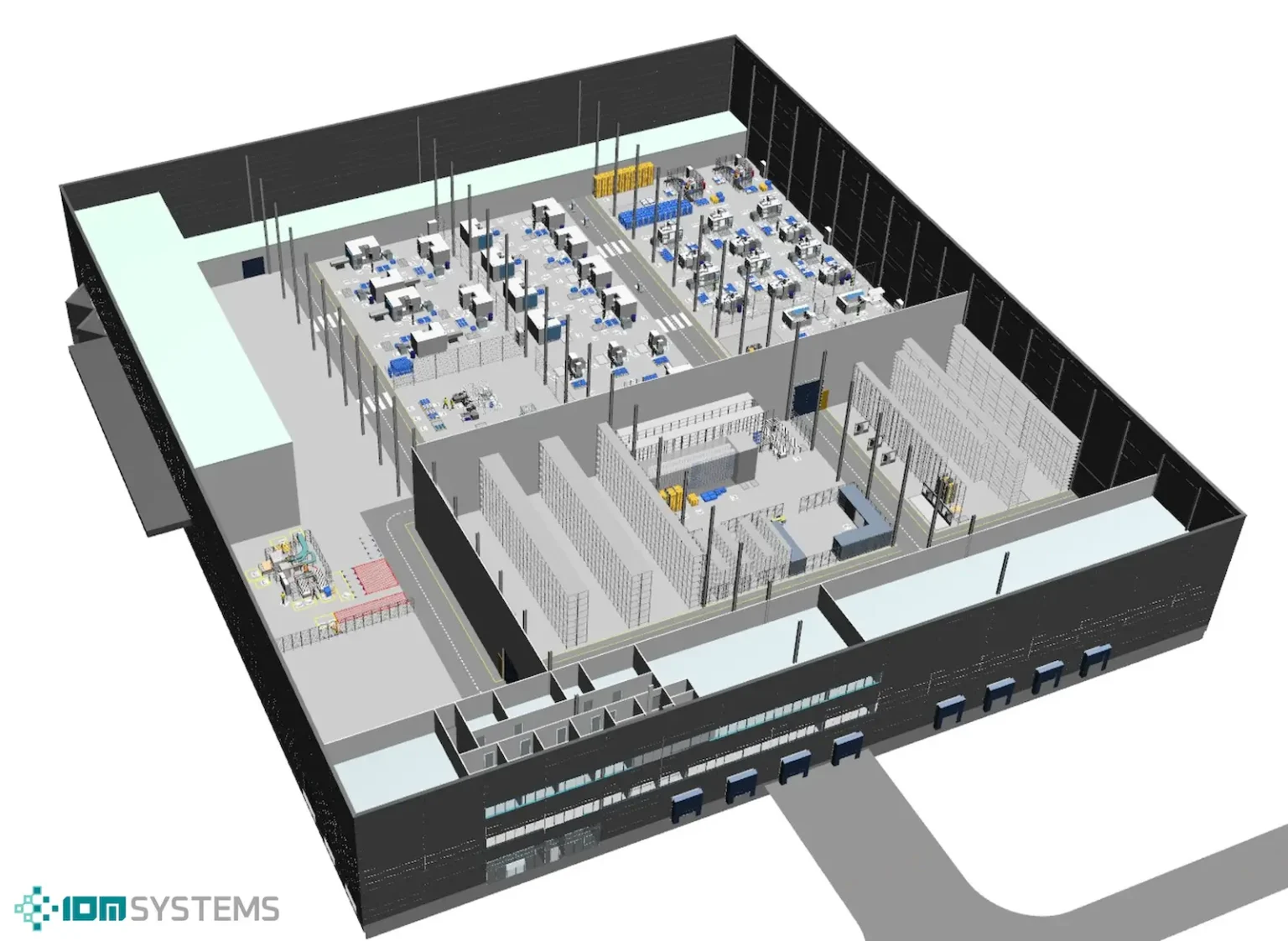

At a client’s existing plant, several issues were identified: excessively long lead times, large WIP buffers, and forklifts that moved frequently despite low utilisation. Additional complexity came from processing many seed varieties with strong seasonality—capacities must follow weather and harvest windows, while varieties mature at different times. The main challenge was to understand current operations and to create and evaluate different future factory concepts to reduce non-value-adding time, optimise internal logistics, and improve overall efficiency.

Project objective: Compare and optimise future development options

Main objectives:

- Compare current and future factory concepts.

- Find solutions to reduce non-value-adding time, especially long lead times.

- Optimise the size and number of WIP buffers.

- Optimise forklift utilisation (increase usage efficiency, reduce unnecessary movements).

- Increase scheduling flexibility so the plant can quickly adapt to the seasonal, weather-dependent arrival of different seed varieties.

- Develop future factory concepts that can be introduced step-by-step or with higher levels of automation.

Solution: Build the simulation, develop additional concepts, then analyse them

We modelled the current factory and several future variants using discrete-event simulation. The model was based on on-site surveys and the plant layout. Equipment parameters and the production schedule were provided as separate inputs. Online consultations supported understanding of system logic. The model was validated in multiple rounds against real performance to ensure it reliably represents actual processes.

Key characteristics of the simulation:

- Discrete-event simulation.

- Modelling the current factory with real data.

- Simulation of future concepts: partial upgrades and higher levels of full automation.

- User-friendly GUI with easily adjustable parameters.

- Scenario creation for various logistics and technological setups.

Analysis and evaluation:

We compared three main manufacturing versions:

- Current factory

- Long lead times → high non-value-adding time.

- Large WIP buffers: ~50% of floor area used for storage.

- Many forklifts with low utilisation and significant idle travel.

- First future concept

- Integrated colour sorter and cold store → reduced lead times.

- Some lead times were eliminated, but several remained.

- Forklift utilisation improved on an annual basis; the distance to the cold store still posed a problem.

- “Ideal” future factory

- Silo capacity before the colour sorter (sorting seeds by colour) proved insufficient → development proposals: a second colour sorter, larger silos, shorter lead times.

- Pull-flow WIP buffer remained oversized.

- Optimised logistics: fewer forklifts, shorter routes, lower traffic load. Forklift utilisation improved per shift, but some unnecessary movements persisted.

- Current factory

Results: Evaluating concepts against the original factory

- The first concept achieved lead-time reductions, but most WIP storage issues remained.

- The ideal concept showed that reconfiguring storage and lead times can deliver significant savings and efficiency gains.

- The number of forklifts and their routes can be substantially optimised—even tailored per shift.

- The model also highlighted that, by incorporating harvest seasons and weather factors into scheduling, seasonal congestion and capacity issues can be anticipated and mitigated.

- The simulation clearly identified where non-value-adding times arise and which interventions deliver real improvements.

Solution and conclusion

The project demonstrated that current system issues—long lead times, oversized buffers, underutilised logistics—can be effectively addressed with well-designed factory concepts. The different simulations not only enabled comparison, but also guided both incremental and more radical improvements.

Key takeaways:

- The main sources of non-value-adding time are long lead times and oversized WIP buffers.

- Optimising the forklift fleet saves not only cost, but also space and time.

- Automated material flow does not necessarily reduce flexibility.

- Even “small-step” improvements can deliver significant progress.

Why was this project outstanding?

This project modelled a complex factory using real data, then illuminated possible improvement paths by simulating different development concepts. The approach made it possible to forecast the impact of future investments and supported strategic decision-making with concrete data.

Summary

The simulation model delivered in this project is a strong example of how discrete-event simulation can be used to analyse, compare, and optimise the operation of a complex factory. The work not only enabled deep understanding of current production, but also uncovered forward-looking development opportunities—backed by measurable, model-based results.