Goals

- Detailed modelling of the shop-floor operation, including production, transport, and storage processes.

- Automatic import and replay of historical production data in a simulation environment.

- Identification of problem areas and risk-free testing of improvement ideas.

- Creation of a flexible model the client can use — and further develop — independently on a daily basis.

Challenges

- Processing and cleaning a large volume of heterogeneous-format production data.

- Incomplete documentation of warehousing and transport processes.

- Accurate reconstruction of real-world operation and production logics.

- Designing the model so the client, with full access and training, can operate it independently later on.

Solution

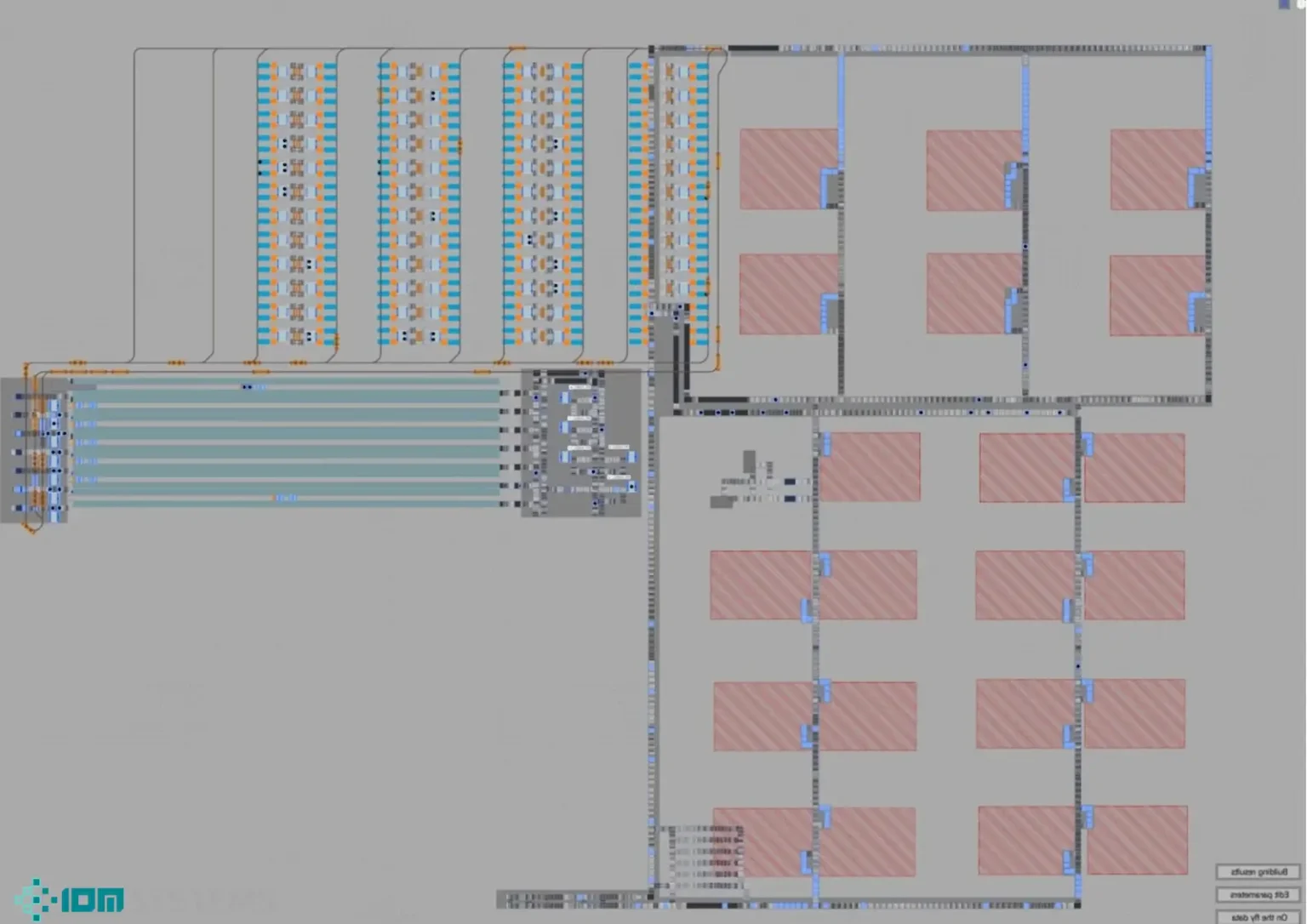

- A simulation model built in Siemens Plant Simulation, based on real data.

- The production area layout and a structured Excel database served as the foundation.

- On-site walk-throughs and online consultations to clarify operating logics.

- Multi-stage data cleaning and filtering to process production data.

- Reconstruction of missing logistics processes based on data analysis and observation.

- Full model access, licence purchase, and client-side simulation training.

Results

- Internal material-handling losses reduced by 15%.

- Production planning accuracy and capacity utilisation improved by 20%.

- €250.000/year savings by optimising logistics and storage processes.

- The client can independently replay historical production data and test improvements risk-free.

Challenge: Mapping and optimising real production with simulation

In one hall of an international tyre manufacturer, operations were not sufficiently efficient. Although daily production appeared to run smoothly, management sensed that certain areas were not performing at their best. The reason was that the production logic still matched a product mix from 5–10 years earlier, when far fewer variants were produced in larger series. Since then, the number of variants has multiplied, so production runs in smaller but far more batches. As a result, bottlenecks emerged in completely different places than before. The aim was to create a simulation that could replay past production processes using real data, providing an accurate picture of the factory’s operation and its weak points.

Project objective: Create a runnable, replayable model based on real data

The project set the following objectives:

- Detailed mapping of the shop-floor operation, including production, transport, and storage processes.

- Designing the simulation model so it can automatically read the production data automatically recorded by the client’s MES.

- Replay and analysis of past operation within the simulation environment.

- Creating a system in which the client can make modifications and test various improvement ideas independently.

Solution: A realistic model capable of ingesting production data

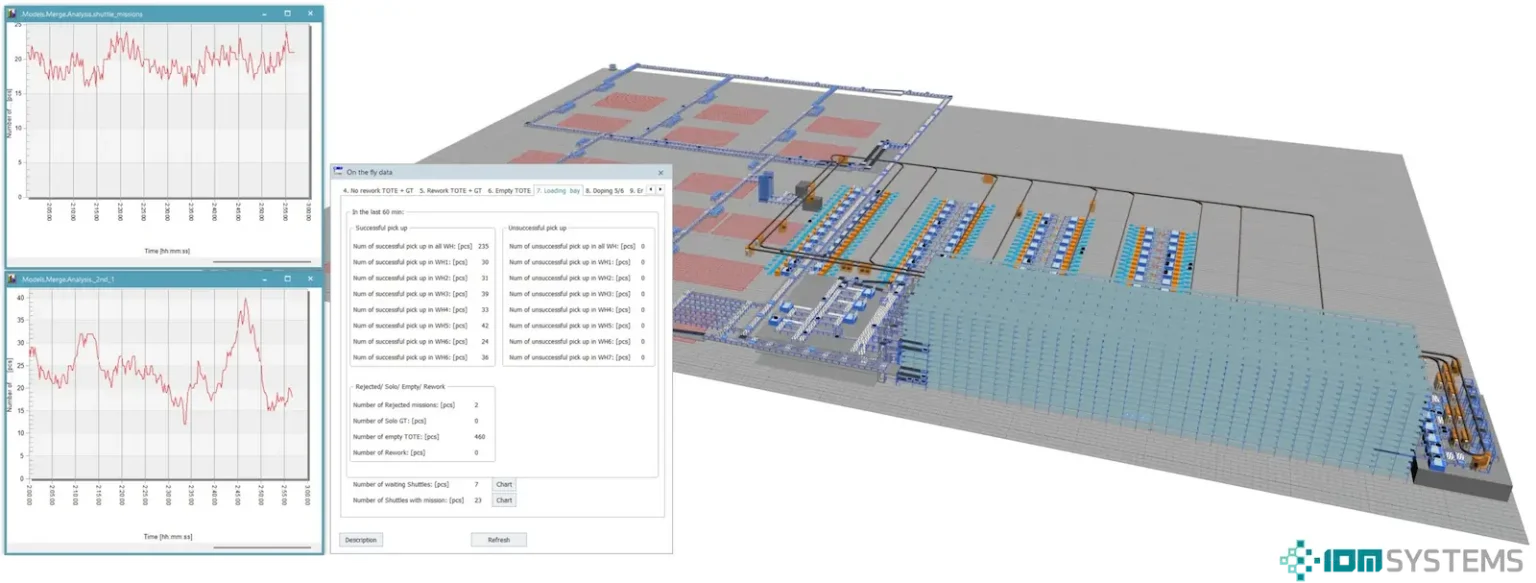

We built a detailed model in Siemens Plant Simulation that mapped the full flow of production, transport, and storage.

The precise layout of the production area and the client-maintained Excel database served as the basis. On-site walk-throughs and online reviews helped clarify operating logics.

In addition to developing the model, multi-stage validation played a key role. During this process, we checked and refined the entire system not all at once, but by breaking it down into subsystems.

We validated the operation of the production machines, the transport processes, the automated warehouse, the warehouse retrieval logic, and the furnace servicing separately. We compared each subsystem’s outputs with historical production data and on-site observations; by integrating the modules we created a comprehensive model that faithfully reflected both the subsystems and the operation of the entire plant unit.

One of the biggest challenges was processing the large volume of production data — not only significant in quantity but differing in format and accuracy. Processing required multi-stage cleaning and filtering before data entered the model. Documentation of warehousing and transport processes was particularly incomplete, so we reconstructed these by combining on-site observation with data analysis.

A noteworthy aspect of the project was that the client requested full access to the model’s source, purchased licences, and received simulation training, enabling them to develop and use the model independently over the long term.

Result: Replayable reality and targeted optimisation

The project delivered a simulation model capable of replaying past events based on stored production data. This enabled:

- Examination of real production behaviour and identification of problem areas.

- Discovery of logistics processes previously unknown to the client or difficult to follow.

- Precise determination of the causes of identified errors, losses, and inefficiencies.

- Trying out alternative operating logics and improvements without stoppages or risk.

Why was this project outstanding?

This simulation project was built around replaying past events — a rare and particularly valuable function in a manufacturing environment. We created a flexible model that not only supports understanding the present, but also enables future improvements. With the model in hand, the client can independently replay and evaluate past production, as well as test future developments and make decisions based on them.

Summary

This project is an excellent example of how discrete-event simulation can support uncovering manufacturing problems, processing the past, and optimising the future. With such a model, the client no longer merely reacts to problems; they can actively shape production — grounded in real data and validated simulation.