Goals

- Shortening the commissioning time of a fully automated, turnkey final inspection cell

- Optimising EOL cell operation with digital manufacturing technologies

- Full lifecycle project support with digital manufacturing tools

Challenges

- Determining the optimal operation and test sequence of a multi-station cell

- Identifying bottlenecks to meet cycle times

- Limited possibility for longer real-time testing due to continuous production

Solution

- Proof of concept and detailed simulations with several layout and process variants

- Offline robot programming for all 5 product types to reduce field commissioning time

- Virtual commissioning (SIMIT, PLCSim Advanced, Technomatix Process Simulate, Zenon, Gocator Emulator)

- Emulation blocks to simulate the operation of PLC and real devices (He tester, CT, camera, code reader, balance)

- Fine-tuned simulation adapted to real system operation, taking into account communication delays and physical characteristics

Results

- 10-15% field commissioning time reduction thanks to virtual testing

- Cost savings of thousands of EUR by minimising production downtime

- Achieving the required cycle time by targeting bottlenecks

- A sustainable system that can be quickly adapted to new product types and future expansions

Automated final inspection in the automotive industry supported by digital simulation

Shortening the commissioning period is particularly important in automotive projects. This need implies the need for virtual commissioning. In the design and installation of the custom-designed cell presented below, we have used the full range of digital manufacturing technologies - from proof of concept simulation, detailed layout optimisation and offline robot programming to virtual commissioning and post-optimisation.

From design to virtual plant

Already in the design phase, several proof of concept (PoC) simulations were performed to validate the engineering concepts in terms of yield, cycle time and process logic. The need for PoC simulation arose from the need to investigate the operation of a cell with several stations, where the interaction of processes was not always self-evident. The simulations were used to test several concepts, and as a result of discussions with the customer, the optimal test sequence, cell layout and extensibility options were determined.

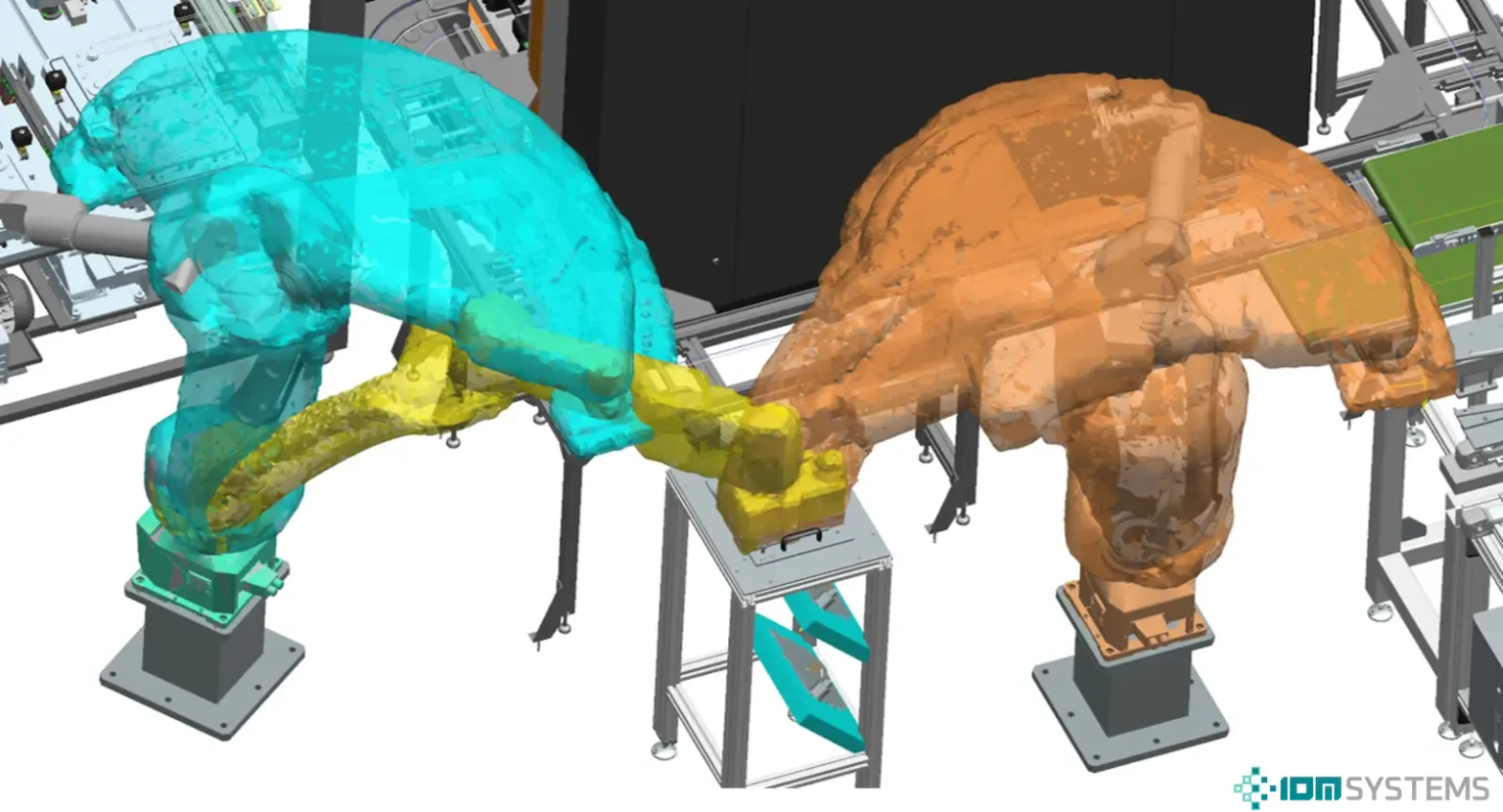

Once the concept was finalised, we created a detailed simulation model of the cell to be built. In this case, not only the cycle time per station, but also the individual sub-processes and movement times were modelled, taking into account the mechanical calculations. Simultaneous offline robot programming with PLC programming was used to prepare the actual robot programs for all 5 product types in addition to the robot programming structure. This meant that only the training of the individual points was required in the field, saving considerable commissioning time.

Virtual commissioning

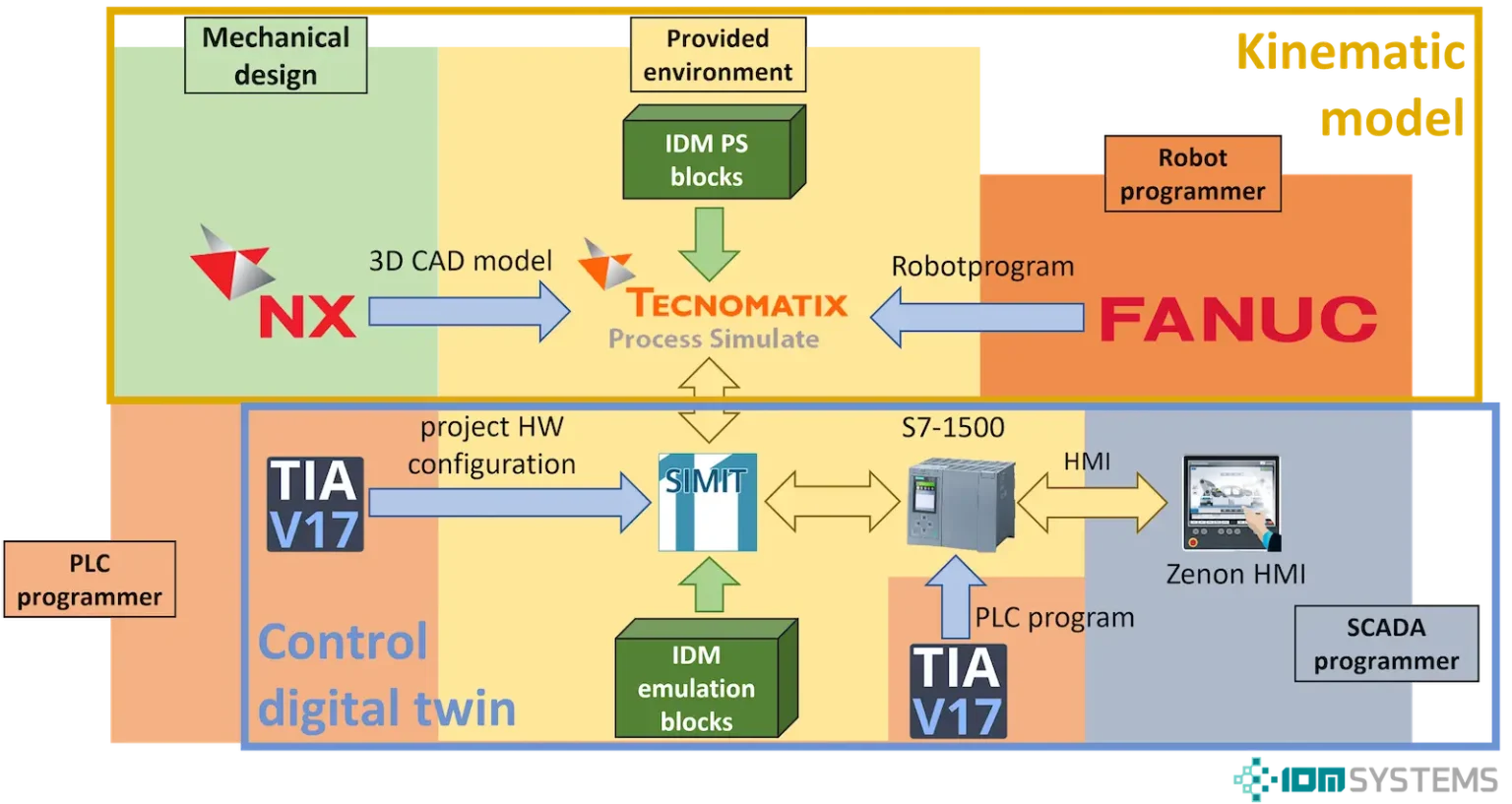

In virtual deployment, the goal is not to fully map the communication with each device, but only to test the execution logic. We need to make the PLC believe that the physical devices (drives, code readers, cameras, etc.) are present, which we can do by using emulation components. These emulation blocks are created in SIMIT software in parallel with the development of the PLC program for the various devices present in the cell: He tester, CT camera, code reader, balance, etc. SIMIT can be used to connect different software in addition to creating emulation components, and thus plays a central role in virtual commissioning by mapping (emulating) the communication protocols.

The software environment used in the virtual deployment was built as follows:

- Technomatix Process Simulate: display 3D CAD model and run robot program

- Simit: running emulation blocks and linking PLC program - 3D CAD model

- PLCSim Advanced: run virtual PLC

- Zenon: running a virtual HMI

- Gocator Emulator: emulation of LMI measurement system and related communication

With the help of virtual commissioning, we were able to successfully test automated processes and logic, as well as exceptional cases such as evacuation, error reactions in an office environment. These test cases have been documented and their success and the points where further optimisation may be needed have been recorded using a validation protocol. Another important point was the testing of the robot program execution and PLC-robot communication in the virtual environment. The Process Simulate software also provided an opportunity for collision detection, as the two robots shared a common workspace. These test cases saved considerable on-site time and cost.

After commissioning, we were initially 10% over the target cycle time, but it was not clear which part of the cell was the bottleneck.

(Note: It is common for virtual setups to differ by around 20% in cycle time due to simulation vs. real-world execution time.)

In addition, the test on a real cell for a longer period of time, as we had to be in active production immediately after commissioning and the cell could not be taken out of production.

As a result, the detailed simulation was refined to match the real system so that the cycle times of all real and virtual sub-processes are the same. In other words, the simulation has been modified to take into account the communication delays (sensor signalling times, actuator behaviour, etc.) and movements (pneumatic movements, friction delays) experienced in the real system.

We could then easily run different test scenarios on the simulation model without having to implement them on the real system.

Finally, we were able to find the bottlenecks in the cell - the +10% lag was due to several small factors. The simulation model clearly showed that we hit another wall after removing one of these bottlenecks. Based on the simulation results, we made several modifications to the real cell - drive parameterisation, robot program optimisation, modification of the prioritisation logic - to achieve the required cycle time.

As the cell only had to be taken out of production for a short period to load and test the changes, it was possible to minimise production losses caused by optimisation alone.

Long-term benefits

The simulation model, synchronised with the real cell, is also useful for the future because it provides a sustainable and scalable platform on which the customer can pre-test new product types, modified robot grippers or rearranged layouts in the future without any risk.

This development is a good example of how digital simulation and virtual commissioning can make the implementation of complex automation projects in the automotive industry faster, cheaper and more reliable.