Welcome to the world of

Industrial automation and digital manufacturing

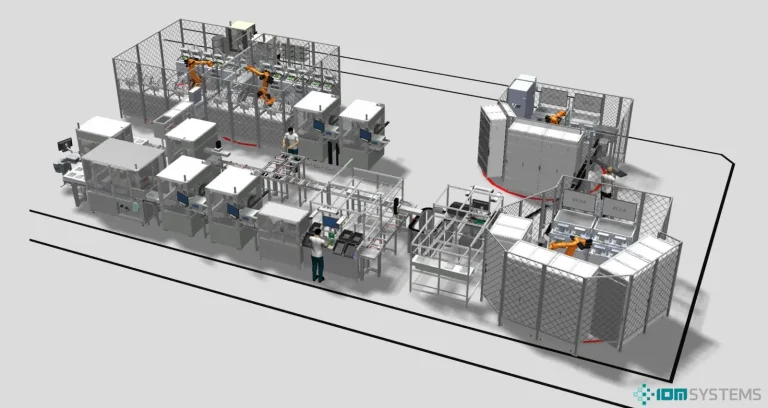

IDM-Systems Zrt. is a high value-added engineering company providing design, implementation and optimisation of complex industrial manufacturing and IT systems, supported by simulation and cyber-physical models, artificial intelligence and machine learning algorithms.

Mechanical Engineering and Manufacturing

Mechanical, electrical and control design and construction of complex, customised industrial equipment, production lines with full engineering support.

Automation and Drive Technology

Integration and modernisation of advanced automation solutions, HMI/Scada and drive systems, including multi-axis synchronised motion control.

Industrial Digitalisation

With digital twins, simulations and data-driven systems, you can make faster, more informed decisions - enabling us to optimise your manufacturing and logistics processes.

Manufacturing Intelligence

Development of data-driven decision support through artificial intelligence and machine learning-enabled industrial analytics, development of custom industrial software

Distribution

Sales and technical support of industrial software and hardware in collaboration with our international strategic and technology partners.

20 years of expertise

IDM-Systems Zrt. is a young, dynamically growing, 100% Hungarian-owned company, where more than 80% of the team are engineers and IT professionals. Our team's key personnel have 15-30 years of experience in industrial automation, machine design, machine manufacturing, digitalization and industrial IT solutions in both domestic and international medium and large enterprise environments. We are passionate about technological advances, increasing manufacturing efficiency and implementing smart, data-driven solutions.

Our mission

We believe that

the worlds of traditional and digital manufacturing will become even more closely intertwined in the future, and unified but digital solutions will best serve the long-term development and competitiveness of manufacturing companies.

In this rapid transformation

we want to support our customers step by step, adapting to their current needs, whether it is a simple control or machine technology task, or even the optimisation of a complex production process using the latest digitalisation tools.

News

Follow our company's milestones, professional accolades and latest technology solutions to help our customers stay competitive.

IDM-Systems Zrt. at the ZenonIZE25 conference

IDM-Systems Zrt. will not only have a booth at the zenonIZE25 – Inspiration Days conference, but will also surprise visitors with a special online game that simulates the challenges of modern production management.

IDM-Systems Zrt. 5-year anniversary

IDM-Systems Zrt. celebrated its 5th anniversary with a special programme: a visit to the Unicum House and an exclusive wine tasting made the event memorable, bringing the team together and celebrating our joint successes.

COPA-DATA recognition for IDM digitisation activities

COPA-DATA's international blog praised IDM-Systems' digital twin approach, which provides comprehensive support throughout the entire lifecycle of industrial systems, from virtual commissioning to real-time, data-driven optimisation.

Success Stories

Our success stories show how we put our partners' ideas into practice - whether it's the turnkey delivery of automation systems, the use of digital twins or the integration of IIoT solutions.

Performance testing of existing or planned production cells

The performance and bottlenecks of a complex production cell were modelled using discrete event simulation in the Siemens Plant Simulation environment. The analysis confirmed that the target of 1.500 parts per day can be safely achieved, while providing accurate optimisation recommendations for system improvement.

Multi-level digital twin: a technical overview of the next evolution of digital twins in production

With the Multi-Level Digital Twin concept, IDM-Systems Zrt. offers an integrated, future-proof solution for digital twins in production, combining classic virtual commissioning (Digital Asset Twin) and real-time data-driven operation (Operational Twin).

Automatic end-of-line robotic sorting and palletizing solution

An intelligent robotic palletising system automates quality control, sorting and stacking at the end of a production line handling cartons. Ideal for high volume, repetitive palletising tasks.

Satisfied Customers and Partners

We are proud to have been chosen as a partner by international and domestic companies who place a high value on reliability, technical excellence and forward-thinking solutions.

Our Technology Partners

Our innovation efforts are supported by international technology partners who are global leaders in industrial digitalisation, automation and software development, and with whom we share a similar mission and values.

Satisfied Customers

We are proud to have been chosen as a partner by international and domestic companies who place a high value on reliability, technical excellence and forward-thinking solutions.

R+D+I Partners

Our product development is backed by scientific collaborations with universities and research institutes, combining practical industrial experience with the latest scientific and algorithmic advances.