Goals

- Full automation of end-of-line palletising and pallet handling processes

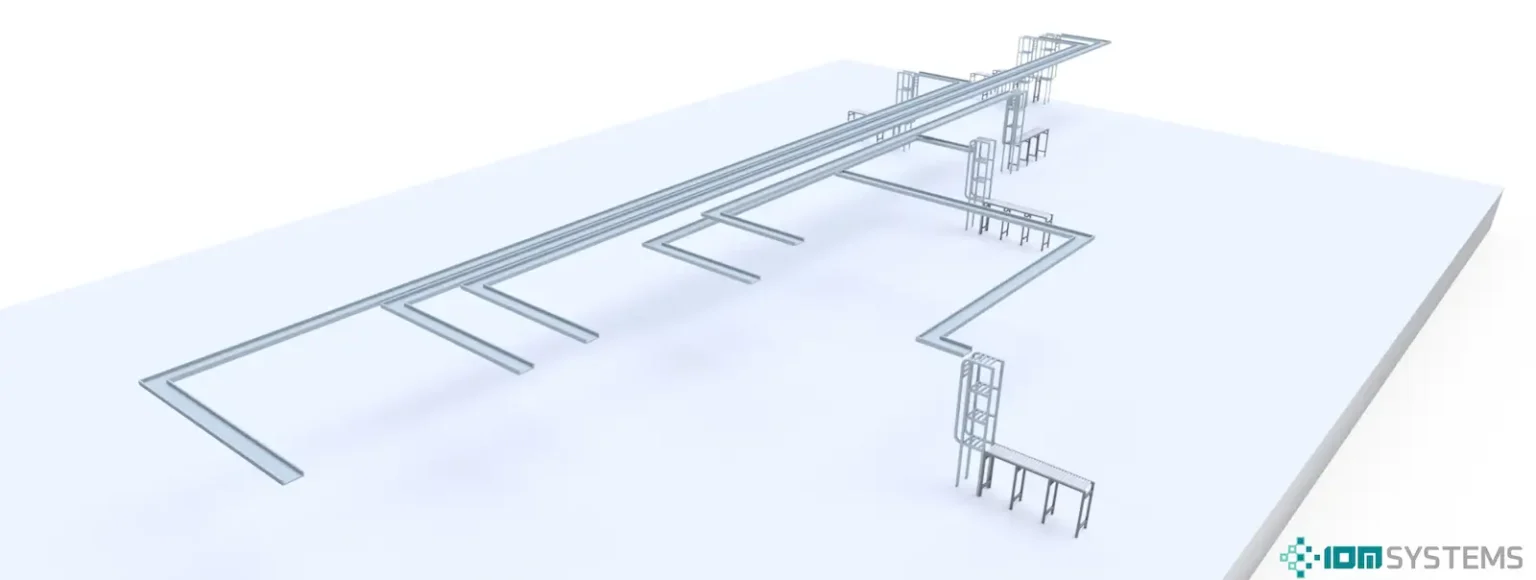

- Installation of a space-saving, overhead conveyor system to optimise the production area

- Flexible handling of multiple product types with varied loading images

Challenges

- Narrow production hall space, which limits the installation of traditional palletising equipment

- Simultaneous handling and separation of multiple products in end-of-line logistics

Solution

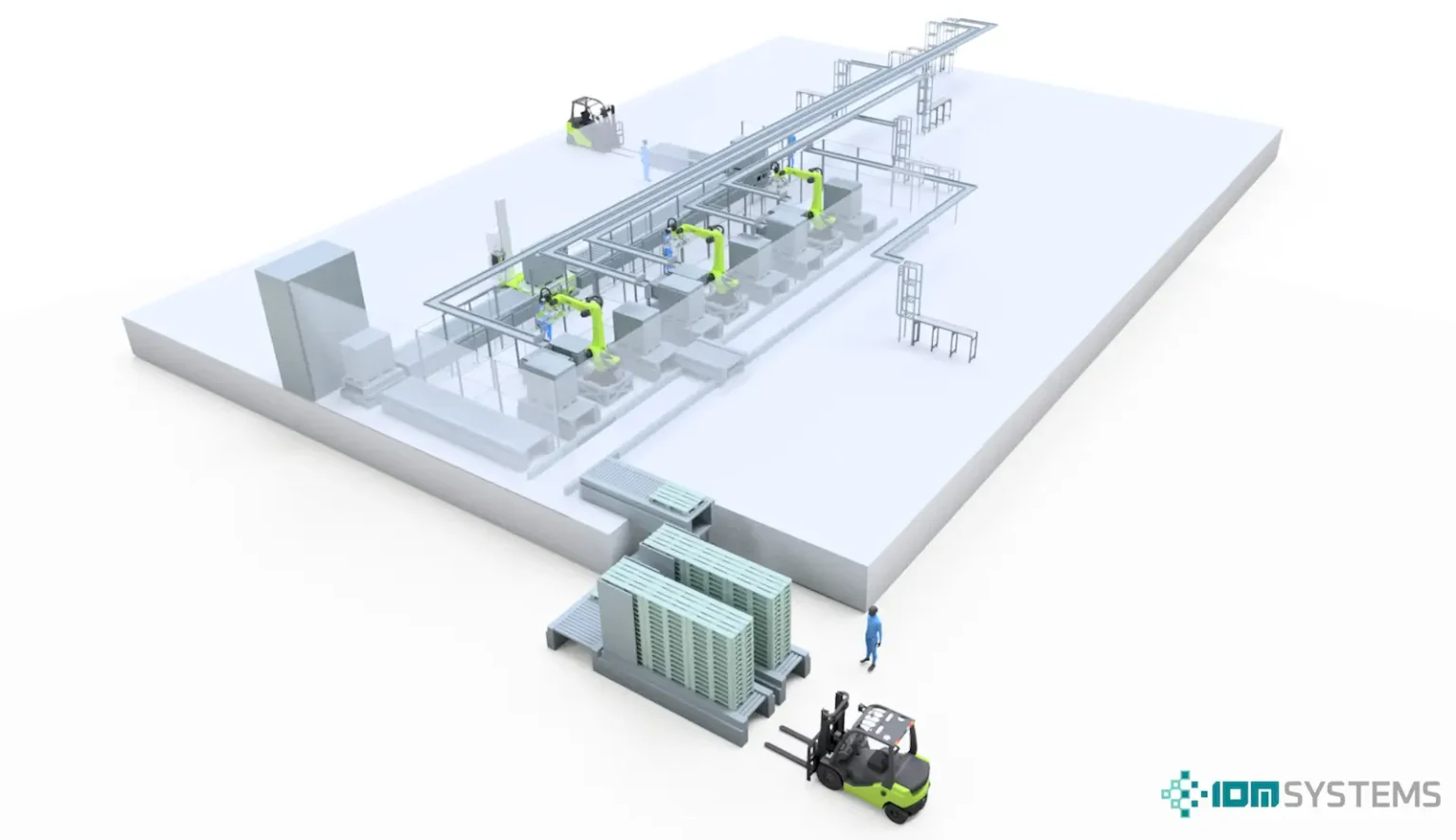

- Overhead conveyor system to maximise free floor space

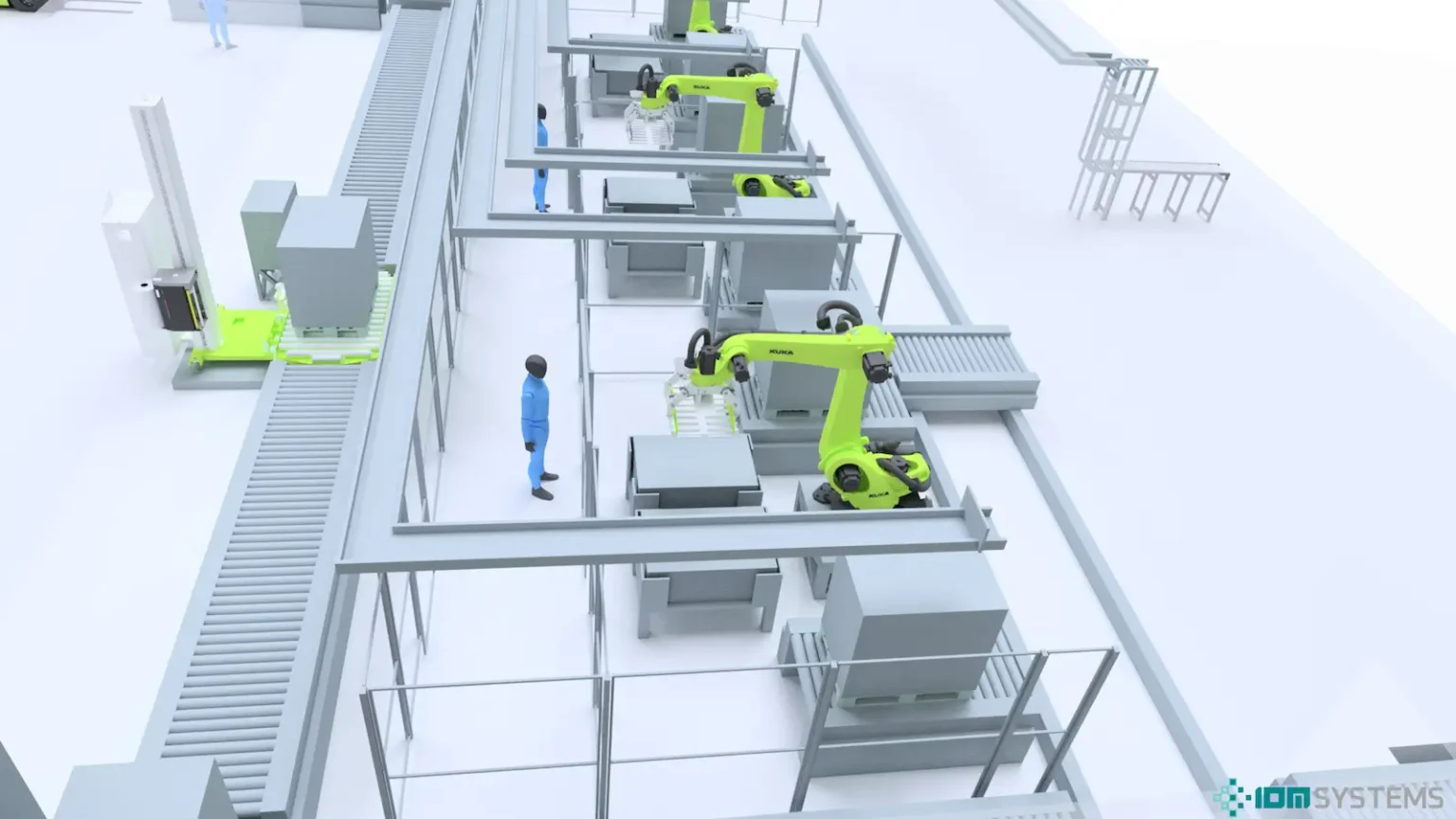

- Parallel operation of multiple robots and palletising stations to increase efficiency

- Integration of automatic foiling and labelling units to cover the entire process

- Advanced security fences and access points for smooth operation

Results

- Significant floor space savings of up to 25-30% with the overhead conveyor system, allowing the installation of additional equipment

- Full automation of palletising, foiling and labelling, reducing operator intervention by 40%

- Flexible, multi-product handling system operating from two conveyors simultaneously - 35% capacity increase

- High safety and smooth operation with minimised downtime: ~50.000 € / year cost savings

Robotic palletising supported by an overhead conveyor - space-saving and complete end-of-line logistics

Our client was looking for an end-of-line solution that would both increase the efficiency of the production line and free up valuable loading space on the shop floor. The unique palletising system designed by IDM-Systems with overhead conveyor, tray lifts, robotic loading logic, automatic foiling and labelling, realises the complete end-of-line logistics under a single, central control. Compact design and advanced safety solutions guarantee reliable, continuous operation even in tight spaces.

Who is it for?

- For production halls where end-of-line product handling requires a space-saving and automated solution

- For industrial logistics centres handling several product types in parallel

- For companies that want to minimise manual labour and maximise process safety

Main area of use

- Production halls

- Industrial logistics centres

- Companies seeking end-to-end automation

The main parts of the system

1. Conveyor belts from production machines

Finished products in trays are rolled off each production machine and transported to the tray lift by conveyor belt.

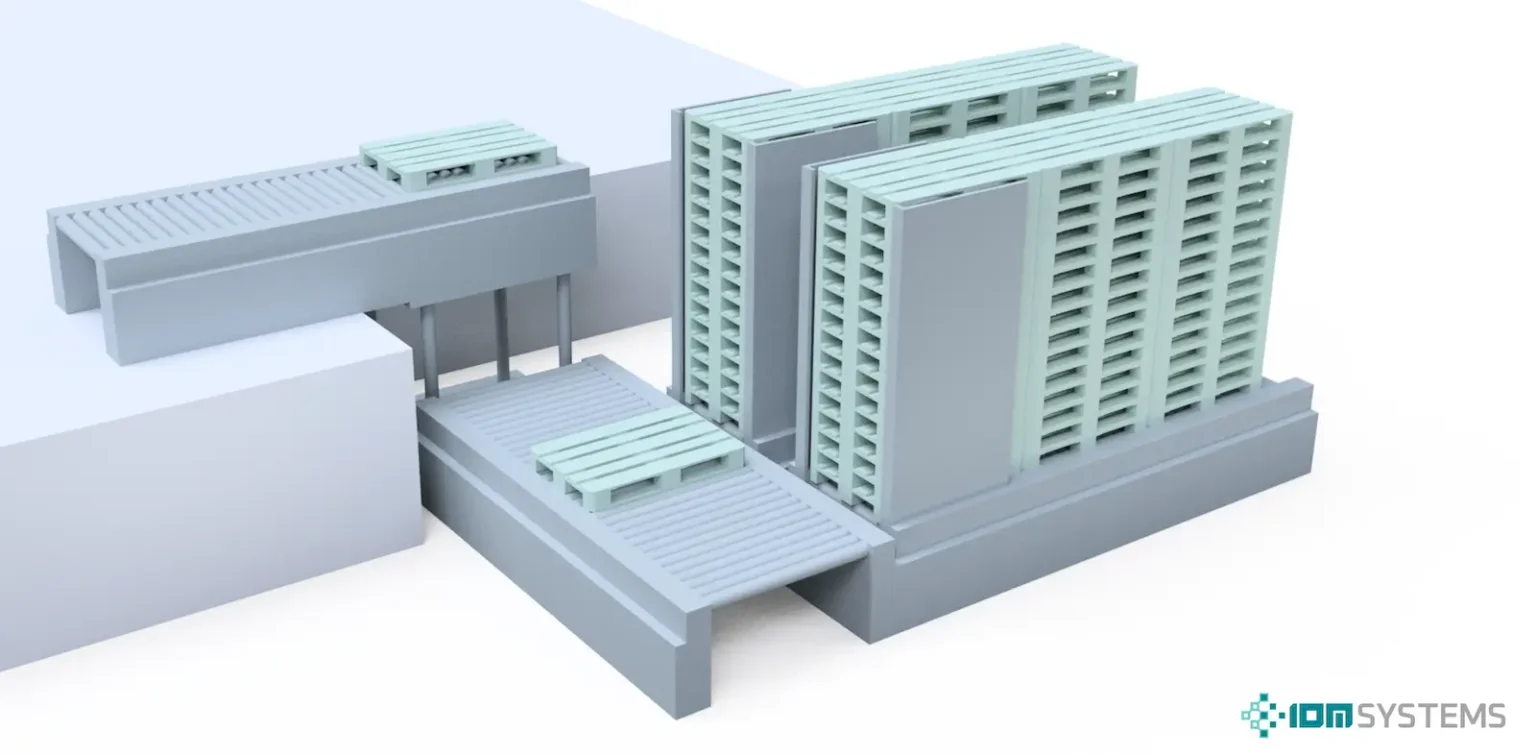

2. Tray lifts and overhead conveyor system

The incoming cartons are lifted by a lift to a height above the residence zone (~3.2 m), from where they are conveyed to the palletising stations. The advantage of the overhead conveyor system is that, with the use of a suitable protective enclosure, the space underneath the conveyor system can be used for additional purposes, machinery and other equipment can be installed there.

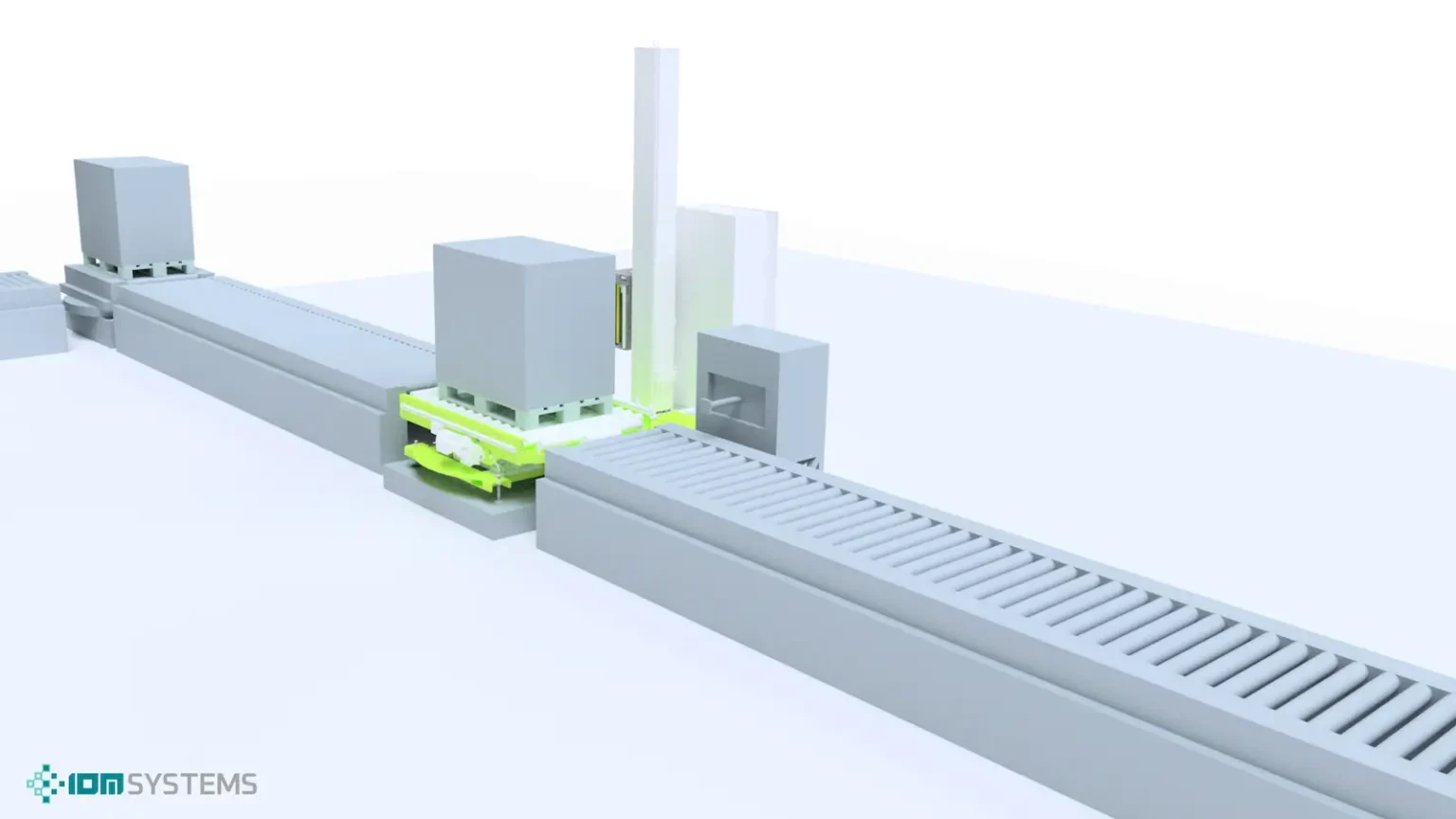

3. Sorting machine units and robot pick-up positions

The carton trays are stopped and sorted at the end of the conveyor belt by means of stoppers and diverters, ensuring a constant position for the robot pick-up.

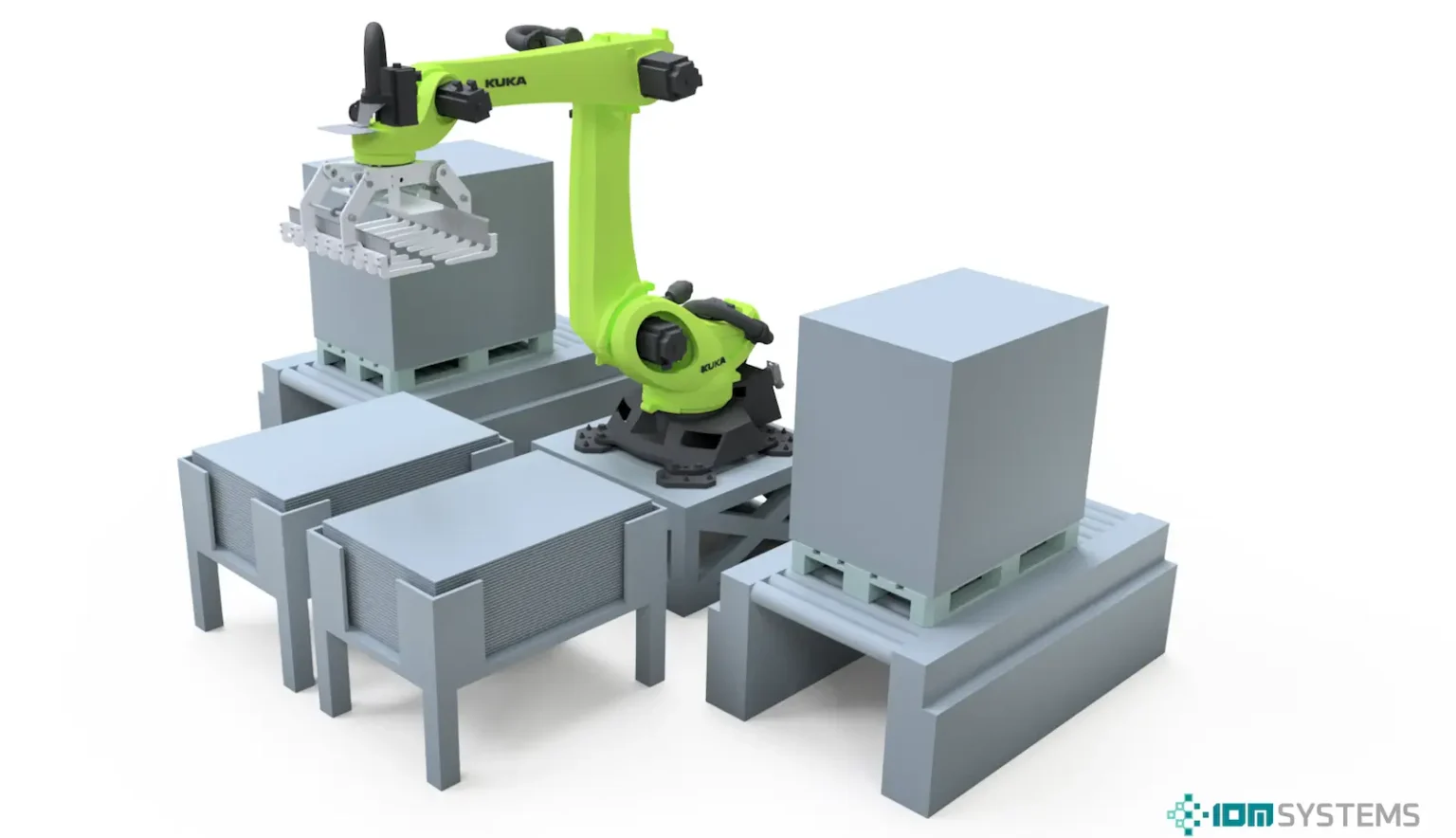

4. Palletising robots

The positioned carton trays are picked up by the palletising robot with a special robot tool and placed on a EUR pallet according to the given palletising picture. 4 trays are loaded at a time by the robot (according to the stacking picture, it is possible that less than 4 trays are loaded at a time, this is possible due to the sectional design of the robot tool).

A robot loads from two conveyors at the same time, two different products on two separate pallets. In total, there are 3 robots and 6 palletising stations in the cell.

For certain product types, the palletising robot inserts cardboard trays between each row. It can do this with the same robot tool.

5. Stacking stations

The robot builds the pallet from the individual cardboard trays onto the pallet, based on the palletisation image and the required pallet height for the pallet dedicated to the article number. Only one type of carton tray can be placed on a pallet. The orientation of the cardboard trays is defined. After the pallet is completed, a pallet truck moves the pallet from the palletising station to the next station.

6. Pallet truck

The task of the pallet truck is to transfer the finished pallets from the loading station to the conveyor in front of the pallet wrapping workstation, and then to place an empty pallet from the automatic pallet feeder to the empty pallet loading station.

7. Automatic pallet dispensing system

An automatic pallet dispenser can store up to 3 x 15 empty pallets. To ensure redundancy and a higher degree of system autonomy, 2 pallet handling units have been added to the system. The pallets are loaded by an operator using a forklift. The pallets are automatically discharged to the pallet truck. In the present design, there is a 1.5 m difference in level between the pallet infeed and the palletising cell, so that there is also a lift between the 2 units. After the pallet has been fed from the palletiser, the empty pallet is conveyed on a conveyor track to the elevator, where it is lifted up to the level difference and is transported to the pallet truck.

8. Automatic pallet wrapping and labelling

The pallets waiting to be wrapped are fed one by one into the wrapping machine by means of a conveyor system, where the pallets are wrapped. Different types of wrapping are possible, depending on the type of product: some pallets are wrapped with a cover film, others do not need one. After wrapping, the pallets are labelled.

9. Label applicator

After wrapping, the pallets are labelled for identification by means of a pallet rotating conveyor. Once labelled and correctly oriented, the finished pallets are transported to the end point, where the operator moves them using a forklift.

10. Security system

The entire cell is surrounded by a security fence with service doors in several places to allow maintenance and access. Where there is no security fence, there is a masonry wall with adequate strength.

Why is this solution beneficial?

- Space-saving: floor remains free due to overhead conveyor belts

- Fully automated: palletising, foiling, labelling, pallet handling in one system

- Flexible: handling multiple product types and varied loading images

- Secure: advanced protective fences, automated and integrated security features.

- Efficient: several robots and palletising stations work in parallel.

If you want to optimize your end-of-line processes and free up valuable production space, IDM-Systems Zrt. will be happy to help you with a customized solution to meet your needs.